Despite the recent economic revival, the US Manufacturing sector is still a key contributor of the national economy. It supports 12.8million jobs, accounts for one percent of private-sector work, and employs more people than the average American. However, the manufacturing sector's share in national output has dropped since the Great Recession. Its employment percentage has also fallen to less than 12 percent. The manufacturing industry is facing structural problems. These include trade deficits as well as low productivity and output. Although these issues are slowly being addressed, it is not clear what the long-term impact of these issues will be. The US manufacturing sector is in a good place to rebound. However, the United States must decide whether it will make a comeback.

Manufacturing is a capital-intensive sector. As new technologies emerge, the sector is changing. Companies are investing in new technologies to increase productivity and the skills of workers. They also develop a workforce of future workers. Additionally, they invest in their existing workforce. This is helping manufacturers to be more competitive in the market. Firms also seek to strengthen supply chains to avoid future disruptions.

Manufacturers are confronting increasing costs due to supply chain problems. The US can address these problems by strengthening its innovation systems. The US will need not engage in tariff wars with any country that wants to export to the US. However, it will be able to maintain open trade relations to keep its manufacturers competitive.

Over the past century, the United States has grown its global presence. Because of this, the United States holds a large percentage of the global oil-and-gas demand. It is however at risk of losing its status as the leading manufacturing country in the world. This is due to the aging of its population and low levels international immigration. It has the potential to increase its competitiveness by investing in new technologies, which will improve production efficiency as well as make it more sustainable.

US manufacturing contributes $2.3 trillion to GDP. This figure represents 20% of the nation’s capital and 35 percent each of productivity gains. In Q1 2018, manufacturing output reached a record $2.00 trillion. This record-breaking figure for US manufacturing was set in Q1 2018. It's also the highest since the Great Recession. Furthermore, the manufacturing sector is performing better than the recovery of its labor market.

The United States has the second-largest global manufacturing presence, after China. Manufacturing makes up 60 percent of the nation's exports and accounts for a substantial share of business R&D spending. However, manufacturing output declined from the fourth quarter of 2007 to the first quarter of 2009. Moreover, the share of manufacturing output grew in only a few states. Manufacturing is more prevalent in the Eighth District, and many states have seen an increase in manufacturing output.

Manufacturing output fell by 15.2 % from 2007's fourth quarter. Manufacturing output declined by 6.4 percent in the first quarter of 2009. However, manufacturing output increased in Illinois and Indiana as well as Ohio and Michigan.

FAQ

What does manufacturing mean?

Manufacturing Industries are businesses that produce products for sale. These products are sold to consumers. These companies use various processes such as production, distribution, retailing, management, etc., to fulfill this purpose. They produce goods from raw materials by using machines and other machinery. This includes all types manufactured goods such as clothing, building materials, furniture, electronics, tools and machinery.

What is the job of a logistics manger?

Logistics managers make sure all goods are delivered on schedule and without damage. This is accomplished by using the experience and knowledge gained from working with company products. He/she must also ensure sufficient stock to meet the demand.

Is automation important for manufacturing?

Automation is important not only for manufacturers but also for service providers. They can provide services more quickly and efficiently thanks to automation. It also helps to reduce costs and improve productivity.

What are the 7 Rs of logistics?

The acronym "7R's" of Logistics stands for seven principles that underpin logistics management. It was developed by International Association of Business Logisticians (IABL), and published as part of their "Seven Principles of Logistics Management Series" in 2004.

The acronym is made up of the following letters:

-

Responsible - ensure that all actions taken are within legal requirements and are not harmful to others.

-

Reliable – have faith in your ability and capability to keep promises.

-

Reasonable - use resources efficiently and don't waste them.

-

Realistic - Consider all aspects of operations, including environmental impact and cost effectiveness.

-

Respectful - Treat people fairly and equitably

-

You are resourceful and look for ways to save money while increasing productivity.

-

Recognizable - Provide value-added services to customers

What is production planning?

Production Planning refers to the development of a plan for every aspect of production. This document ensures that everything is prepared and available when you are ready for shooting. It should also contain information on achieving the best results on set. This includes information on shooting times, locations, cast lists and crew details.

The first step is to outline what you want to film. You may have already decided where you would like to shoot, or maybe there are specific locations or sets that you want to use. Once you've identified the locations and scenes you want to use, you can begin to plan what elements you need for each scene. Perhaps you have decided that you need to buy a car but aren't sure which model. If this is the case, you might start searching online for car models and then narrow your options by selecting from different makes.

Once you have found the right vehicle, you can think about adding accessories. You might need to have people in the front seats. Maybe you need someone to move around in the back. Maybe you want to change the interior color from black to white? These questions will help to determine the style and feel of your car. The type of shots that you are looking for is another thing to consider. You will be filming close-ups and wide angles. Perhaps you want to show the engine or the steering wheel? These details will help identify the exact car you wish to film.

Once you have established all the details, you can create a schedule. You can use a schedule to determine when and where you need it to be shot. A schedule for each day will detail when you should arrive at the location and when you need leave. So everyone is clear about what they need to do. It is possible to make arrangements in advance for additional staff if you are looking to hire. You should not hire anyone who doesn't show up because of your inaction.

Your schedule will also have to be adjusted to reflect the number of days required to film. Some projects take only a few days while others can last several weeks. You should consider whether you will need more than one shot per week when creating your schedule. Shooting multiple takes over the same location will increase costs and take longer to complete. It is better to be cautious and take fewer shots than you risk losing money if you are not sure if multiple takes are necessary.

Budgeting is another crucial aspect of production plan. Setting a realistic budget is essential as it will allow you to work within your means. Remember that you can always reduce the budget later on if you run into unforeseen problems. However, it is important not to overestimate the amount that you will spend. If you underestimate the cost of something, you will have less money left after paying for other items.

Planning production is a tedious process. Once you have a good understanding of how everything works together, planning future projects becomes easy.

Why is logistics important for manufacturing?

Logistics are essential to any business. They enable you to achieve outstanding results by helping manage product flow from raw materials through to finished goods.

Logistics play an important role in reducing costs as well as increasing efficiency.

What types of jobs can you find in logistics

There are many kinds of jobs available within logistics. These are some of the jobs available in logistics:

-

Warehouse workers – They load, unload and transport pallets and trucks.

-

Transportation drivers: They drive trucks and trailers and deliver goods and make pick-ups.

-

Freight handlers - They sort and pack freight in warehouses.

-

Inventory managers: They are responsible for the inventory and management of warehouses.

-

Sales reps - They sell products and services to customers.

-

Logistics coordinators are responsible for organizing and planning logistics operations.

-

Purchasing agents: They are responsible for purchasing goods and services to support company operations.

-

Customer service representatives - Answer calls and email from customers.

-

Shipping clerks - They process shipping orders and issue bills.

-

Order fillers are people who fill orders based only on what was ordered.

-

Quality control inspectors (QCI) - They inspect all incoming and departing products for potential defects.

-

Others - There are many types of jobs in logistics such as transport supervisors and cargo specialists.

Statistics

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

External Links

How To

How to Use the Just-In-Time Method in Production

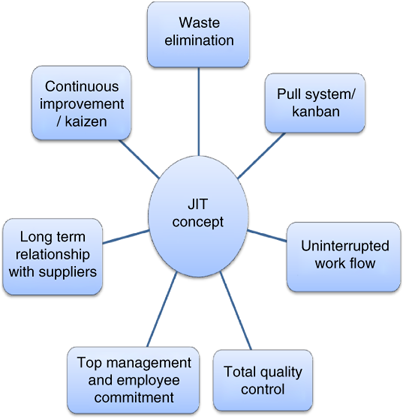

Just-intime (JIT), which is a method to minimize costs and maximize efficiency in business process, is one way. It's a way to ensure that you get the right resources at just the right time. This means that you only pay for what you actually use. Frederick Taylor developed the concept while working as foreman in early 1900s. He observed how workers were paid overtime if there were delays in their work. He decided to ensure workers have enough time to do their jobs before starting work to improve productivity.

JIT is a way to plan ahead and make sure you don't waste any money. The entire project should be looked at from start to finish. You need to ensure you have enough resources to tackle any issues that might arise. If you anticipate that there might be problems, you'll have enough people and equipment to fix them. This will prevent you from spending extra money on unnecessary things.

There are many JIT methods.

-

Demand-driven: This is a type of JIT where you order the parts/materials needed for your project regularly. This will enable you to keep track of how much material is left after you use it. It will also allow you to predict how long it takes to produce more.

-

Inventory-based: This allows you to store the materials necessary for your projects in advance. This allows you to predict how much you can expect to sell.

-

Project-driven: This method allows you to set aside enough funds for your project. Knowing how much money you have available will help you purchase the correct amount of materials.

-

Resource-based JIT : This is probably the most popular type of JIT. Here you can allocate certain resources based purely on demand. You will, for example, assign more staff to deal with large orders. If you don't have many orders, you'll assign fewer people to handle the workload.

-

Cost-based : This is similar in concept to resource-based. But here, you aren't concerned about how many people your company has but how much each individual costs.

-

Price-based: This is a variant of cost-based. However, instead of focusing on the individual workers' costs, this looks at the total price of the company.

-

Material-based is an alternative to cost-based. Instead of looking at the total cost in the company, this method focuses on the average amount of raw materials that you consume.

-

Time-based JIT: This is another variant of resource-based JIT. Instead of focusing solely on the amount each employee costs, focus on how long it takes for the project to be completed.

-

Quality-based JIT: Another variation on resource-based JIT. Instead of looking at the labor costs and time it takes to make a product, think about its quality.

-

Value-based JIT: One of the most recent forms of JIT. In this instance, you are not concerned about the product's performance or meeting customer expectations. Instead, your goal is to add value to the market.

-

Stock-based: This is an inventory-based method that focuses on the actual number of items being produced at any given time. This method is useful when you want to increase production while decreasing inventory.

-

Just-in time (JIT), planning: This is a combination JIT/supply chain management. It is the process that schedules the delivery of components within a short time of their order. It reduces lead times and improves throughput.