Lean is an abbreviation that is used in the manufacturing industry to describe a set of principles and techniques. It can also serve as a motivating term that encourages process improvement.

The Definition of Lean

If a company wants to become more efficient, they may need to eliminate activities that do not add value to their product or service. This can include idle time, unused equipment, and other resources that are not being utilized to their fullest potential.

Lean management is a system designed to eliminate waste in production. The process is a never-ending one, meaning that it will always need to be adjusted and improved.

Lean is a concept that focuses on what the customer wants and makes it a priority to provide this value. It does not focus on what the business thinks they need. This way, companies can avoid wasting money or time creating products that are not wanted by their customers.

You should be aware that the lean concept can be adapted to any type of industry or production process. This is why lean has become so popular across many different industries.

Lean manufacturing is an old system. It focuses on the delivery of the right product at the right time and in the correct amount. This is a very effective tool for increasing the efficiency of the manufacturing process.

Toyoda was the founder of Toyota, and he defined lean production as eliminating waste. This includes things like waste in the form of defects, which would not be acceptable to the customer.

Toyoda's solution to this was a flow process, which involved workers stopping the production line to inspect a part and removing it if necessary. This allowed the company to fine tune each step of production in order to eliminate defects as they arose and increase productivity.

Jidoka stops production automatically when there's an abnormality. Kaizen is a vital part of lean production.

Kaizen involves continuous improvements for any process. This can be applied to the production of products or any other area in the business that needs an update.

A lot of people don't really understand what lean means, but it is a great concept that helps improve the way businesses run. Lean can help businesses save time and money by improving their processes. It can also help them improve their reputation with customers.

In order to succeed, it's important to keep in mind that leaning is not just a single practice. All levels of an organization will have to improve the process. This is why it is crucial to involve all employees in the process, so that everyone can contribute their ideas and ensure that everything goes smoothly.

FAQ

What is production plan?

Production Planning involves developing a plan for all aspects of the production, including scheduling, budgeting, casting, crew, location, equipment, props, etc. This document aims to ensure that everything is planned and ready when you are ready to shoot. It should also contain information on achieving the best results on set. This information includes locations, crew details and equipment requirements.

First, you need to plan what you want to film. You may already know where you want the film to be shot, or perhaps you have specific locations and sets you wish to use. Once you have identified your locations and scenes it's time to begin figuring out what elements you will need for each one. If you decide you need a car and don't know what model to choose, this could be an example. This is where you can look up car models online and narrow down your options by choosing from different makes and models.

Once you have found the right car, you can start thinking about extras. You might need to have people in the front seats. Or perhaps you need someone walking around the back of the car? Maybe you'd like to change the interior from black to a white color. These questions can help you decide the right look for your car. Another thing you can do is think about what type of shots are desired. What type of shots will you choose? Maybe you want to show the engine and the steering wheel. These details will help identify the exact car you wish to film.

Once you've determined the above, it is time to start creating a calendar. The schedule will show you when to begin shooting and when to stop. The schedule will show you when to get there, what time to leave, and when to return home. This way, everyone knows what they need to do and when. It is possible to make arrangements in advance for additional staff if you are looking to hire. There is no point in hiring someone who won't turn up because you didn't let him know.

When creating your schedule, you will also need to consider the number of days you need to film. Some projects are quick and easy, while others take weeks. You should consider whether you will need more than one shot per week when creating your schedule. Multiple takes of the same location will lead to higher costs and take more time. If you aren't sure whether you need multiple shots, it is best to take fewer photos than you would like.

Budgeting is another important aspect of production planning. As it will allow you and your team to work within your financial means, setting a realistic budget is crucial. Keep in mind that you can always reduce your budget if you face unexpected difficulties. But, don't underestimate how much money you'll spend. Underestimating the cost will result in less money after you have paid for other items.

Production planning is a complicated process. But once you understand how everything works together, it becomes much easier to plan future project.

Why is logistics so important in manufacturing?

Logistics are an essential part of any business. They help you achieve great results by helping you manage all aspects of product flow, from raw materials to finished goods.

Logistics play a key role in reducing expenses and increasing efficiency.

What is the job of a production plan?

Production planners ensure all aspects of the project are delivered within time and budget. They ensure that the product or service is of high quality and meets client requirements.

What are the responsibilities for a manufacturing manager

A manufacturing manager must ensure that all manufacturing processes are efficient and effective. They must also be alert to any potential problems and take appropriate action.

They should also know how to communicate with other departments such as sales and marketing.

They should be up to date on the latest trends and be able apply this knowledge to increase productivity and efficiency.

Do we need to know about Manufacturing Processes before learning about Logistics?

No. No. Understanding the manufacturing process will allow you to better understand logistics.

What skills does a production planner need?

Production planners must be flexible, organized, and able handle multiple tasks. Also, you must be able and willing to communicate with clients and coworkers.

Why automate your warehouse

Modern warehousing has seen automation take center stage. E-commerce has brought increased demand for more efficient and quicker delivery times.

Warehouses have to be flexible to meet changing requirements. Technology investment is necessary to enable warehouses to respond quickly to changing demands. Automating warehouses has many benefits. Here are some of the reasons automation is worth your investment:

-

Increases throughput/productivity

-

Reduces errors

-

Improves accuracy

-

Boosts safety

-

Eliminates bottlenecks

-

Allows companies to scale more easily

-

Makes workers more efficient

-

Gives you visibility into all that is happening in your warehouse

-

Enhances customer experience

-

Improves employee satisfaction

-

This reduces downtime while increasing uptime

-

You can be sure that high-quality products will arrive on time

-

Removes human error

-

This helps to ensure compliance with regulations

Statistics

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

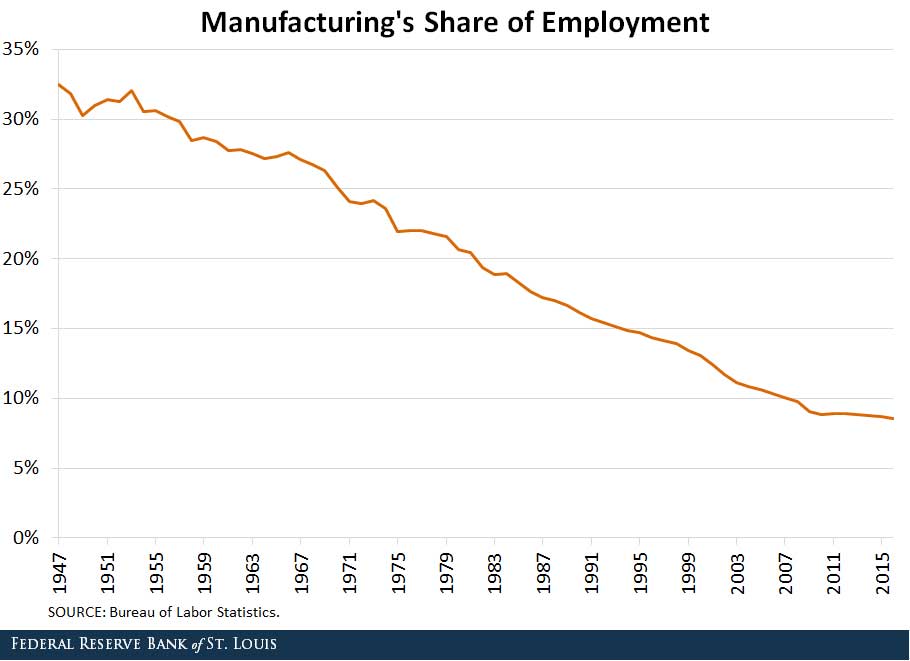

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

External Links

How To

How to Use 5S for Increasing Productivity in Manufacturing

5S stands in for "Sort", the "Set In Order", "Standardize", or "Separate". Toyota Motor Corporation created the 5S methodology in 1954. It allows companies to improve their work environment, thereby achieving greater efficiency.

This method aims to standardize production processes so that they are repeatable, measurable and predictable. It means tasks like cleaning, sorting or packing, labeling, and storing are done every day. Workers can be more productive by knowing what to expect.

There are five steps to implementing 5S, including Sort, Set In Order, Standardize, Separate and Store. Each step requires a different action, which increases efficiency. Sorting things makes it easier to find them later. When you set items in an order, you put items together. Next, organize your inventory into categories and store them in containers that are easily accessible. Finally, when you label your containers, you ensure everything is labeled correctly.

This process requires employees to think critically about how they do their job. Employees need to be able understand their motivations and discover alternative ways to do them. They will need to develop new skills and techniques in order for the 5S system to be implemented.

The 5S method not only increases efficiency but also boosts morale and teamwork. Once they start to notice improvements, they are motivated to keep working towards their goal of increasing efficiency.