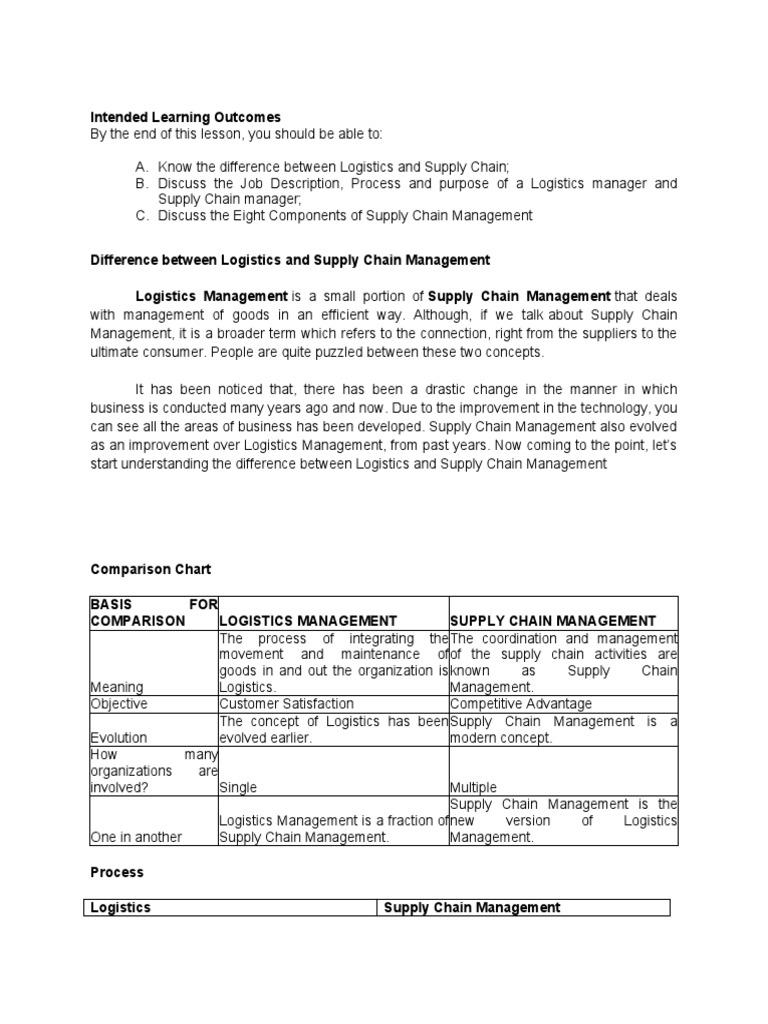

The bill of material (BOM) is an important part in the manufacturing process. It lists every item required for the production of end products. It is crucial for companies whether they sell products directly to customers, or through retail channels. It is essential for companies to keep track and prevent waste. It also helps companies avoid stockouts.

A bill or materials is a detailed, tabular document that lists each component of an assembly. It also lists the parts required to build the assembly. You can purchase the parts and subassemblies from external sources or make them yourself. Each part will need to have a unique number. This allows the assembly team identify the right parts and to gather the necessary materials. It is also important that you note any special requirements on your bill of materials. These special requirements could cause delays or even make the manufacturing process more difficult.

Bills of materials are important to companies because they provide an accurate way to track components and raw materials. They also enable for higher productivity in production. They are useful in preventing stockouts, and they allow companies to forecast sales. These documents allow companies to keep track of the materials used for production, and avoid over-ordering.

A bill-of-materials is a document listing the materials, components and subassemblies that are required to manufacture a product. The bill of material also lists the labor required to complete each stage. It is also important that the bill be inclusive of the supplier(s), for each component. It may also contain other critical details for the production. It is crucial to note that the bill of materials may differ from company to company.

For manufacturing purposes, bill of materials is used to ensure that finished products function properly. Companies can use them to plan and order materials and avoid waste. The bill of material helps manufacturers identify the materials necessary to make a product, and then determine the correct amounts. It is also important that you note that this document will serve as a guideline for the finished product. A bill of materials can be complicated, especially if there are many parts. However, there are software solutions that make it easy to create a bill for materials.

To reflect the requirements and specifications of a project, a bill of materials is prepared. This document can be used to create a blueprint of the final product, or as a communication tool between supply chain and manufacturing partners. This document assists companies in avoiding over-ordering material and keeping track of all components.

A bill of material is essential for any company who sells directly to customers through retail channels. Bills of material allow for greater productivity and profits. They help companies to avoid waste, reduce production mistakes, and prevent stockouts.

FAQ

What skills do production planners need?

To become a successful production planner, you need to be organized, flexible, and able to multitask. Also, you must be able and willing to communicate with clients and coworkers.

How can we reduce manufacturing overproduction?

The key to reducing overproduction lies in developing better ways to manage inventory. This would reduce the amount of time spent on unnecessary activities such as purchasing, storing, and maintaining excess stock. This could help us free up our time for other productive tasks.

Kanban systems are one way to achieve this. A Kanbanboard is a visual tool that allows you to keep track of the work being done. Work items are moved through various states to reach their destination in a Kanban system. Each state represents a different priority.

As an example, if work is progressing from one stage of the process to another, then the current task is complete and can be transferred to the next. But if a task remains in the beginning stages it will stay that way until it reaches its end.

This allows for work to continue moving forward, while also ensuring that there is no work left behind. With a Kanban board, managers can see exactly how much work is being done at any given moment. This information allows managers to adjust their workflow based off real-time data.

Lean manufacturing is another way to manage inventory levels. Lean manufacturing works to eliminate waste throughout every stage of the production chain. Any product that isn't adding value can be considered waste. Some common types of waste include:

-

Overproduction

-

Inventory

-

Unnecessary packaging

-

Material surplus

Manufacturers can reduce their costs and improve their efficiency by using these ideas.

What is the importance of automation in manufacturing?

Automation is important not only for manufacturers but also for service providers. It allows them provide faster and more efficient services. It helps them to lower costs by reducing human errors, and improving productivity.

What is production plan?

Production Planning is the creation of a plan to cover all aspects, such as scheduling, budgeting. Location, crew, equipment, props and other details. This document aims to ensure that everything is planned and ready when you are ready to shoot. It should also provide information about how best to produce the best results while on set. This includes shooting schedules, locations, cast lists, crew details, and equipment requirements.

The first step is to decide what you want. You may have already decided where you would like to shoot, or maybe there are specific locations or sets that you want to use. Once you have identified the scenes and locations, you can start to determine which elements are required for each scene. If you decide you need a car and don't know what model to choose, this could be an example. This is where you can look up car models online and narrow down your options by choosing from different makes and models.

After you've found the perfect car, it's time to start thinking about adding extras. Do you have people who need to be seated in the front seat? Perhaps you have someone who needs to be able to walk around the back of your car. Maybe you want to change the interior color from black to white? These questions will help you determine the exact look and feel of your car. You can also think about the type of shots you want to get. What type of shots will you choose? Maybe the engine or steering wheel is what you are looking to film. These factors will help you determine which car style you want to film.

Once you have determined all of the above, you can move on to creating a schedule. A schedule will tell you when you need to start shooting and when you need to finish. You will need to know when you have to be there, what time you have to leave and when your return home. Everyone will know what they need and when. If you need to hire extra staff, you can make sure you book them in advance. It is not worth hiring someone who won’t show up because you didn’t tell him.

Your schedule will also have to be adjusted to reflect the number of days required to film. Some projects only take one or two days, while others may last weeks. While creating your schedule, it is important to remember whether you will require more than one shot per day. Multiplying takes in the same area will result both in increased costs and a longer time. It's better to be safe than sorry and shoot less takes if you're not certain whether you need more takes.

Another important aspect of production planning is setting budgets. As it will allow you and your team to work within your financial means, setting a realistic budget is crucial. Remember that you can always reduce the budget later on if you run into unforeseen problems. You shouldn't underestimate the amount you'll spend. If you underestimate the cost of something, you will have less money left after paying for other items.

Production planning can be a complex process. However, once you know how everything works together it will become easier to plan future projects.

What does manufacturing industry mean?

Manufacturing Industries is a group of businesses that produce goods for sale. Consumers are the people who purchase these products. These companies employ many processes to achieve this purpose, such as production and distribution, retailing, management and so on. They make goods from raw materials with machines and other equipment. This includes all types manufactured goods such as clothing, building materials, furniture, electronics, tools and machinery.

What are the 7 Rs of logistics?

The acronym 7R's for Logistics stands to represent the seven basic principles in logistics management. It was developed by International Association of Business Logisticians (IABL), and published as part of their "Seven Principles of Logistics Management Series" in 2004.

The acronym is made up of the following letters:

-

Responsible - to ensure that all actions are within the legal requirements and are not detrimental to others.

-

Reliable: Have faith in your ability or the ability to honor any promises made.

-

Reasonable - make sure you use your resources well and don't waste them.

-

Realistic - Take into consideration all aspects of operations including cost-effectiveness, environmental impact, and other factors.

-

Respectful - treat people fairly and equitably.

-

Be resourceful: Look for opportunities to save money or increase productivity.

-

Recognizable - provide customers with value-added services.

What is the best way to learn about manufacturing?

You can learn the most about manufacturing by getting involved in it. If that is not possible, you could always read books or view educational videos.

Statistics

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

External Links

How To

How to Use lean manufacturing in the Production of Goods

Lean manufacturing is a management system that aims at increasing efficiency and reducing waste. It was developed in Japan during the 1970s and 1980s by Taiichi Ohno, who received the Toyota Production System (TPS) award from TPS founder Kanji Toyoda. Michael L. Watkins published the book "The Machine That Changed the World", which was the first to be published about lean manufacturing.

Lean manufacturing can be described as a set or principles that are used to improve quality, speed and cost of products or services. It is about eliminating defects and waste from all stages of the value stream. Lean manufacturing can be described as just-in–time (JIT), total productive maintenance, zero defect (TPM), or even 5S. Lean manufacturing focuses on eliminating non-value-added activities such as rework, inspection, and waiting.

Lean manufacturing can help companies improve their product quality and reduce costs. Additionally, it helps them achieve their goals more quickly and reduces employee turnover. Lean manufacturing has been deemed one of the best ways to manage the entire value-chain, including customers, distributors as well retailers and employees. Lean manufacturing practices are widespread in many industries. For example, Toyota's philosophy underpins its success in automobiles, electronics, appliances, healthcare, chemical engineering, aerospace, paper, food, etc.

Five principles are the basis of lean manufacturing:

-

Define Value - Determine the value that your business brings to society. Also, identify what sets you apart from your competitors.

-

Reduce waste - Get rid of any activity that does not add value to the supply chain.

-

Create Flow: Ensure that the work process flows without interruptions.

-

Standardize & Simplify - Make processes as consistent and repeatable as possible.

-

Develop Relationships: Establish personal relationships both with internal and external stakeholders.

Lean manufacturing isn’t new, but it has seen a renewed interest since 2008 due to the global financial crisis. Many businesses are now using lean manufacturing to improve their competitiveness. Economists think that lean manufacturing is a crucial factor in economic recovery.

Lean manufacturing is now becoming a common practice in the automotive industry, with many benefits. These include higher customer satisfaction, lower inventory levels, lower operating expenses, greater productivity, and improved overall safety.

Any aspect of an enterprise can benefit from Lean manufacturing. Because it makes sure that all value chains are efficient and effectively managed, Lean Manufacturing is particularly helpful for organizations.

There are three main types:

-

Just-in Time Manufacturing: This lean manufacturing method is commonly called "pull systems." JIT is a method in which components are assembled right at the moment of use, rather than being manufactured ahead of time. This strategy aims to decrease lead times, increase availability of parts and reduce inventory.

-

Zero Defects Manufacturing, (ZDM): ZDM is focused on ensuring that no defective products leave the manufacturing facility. If a part is required to be repaired on the assembly line, it should not be scrapped. This applies to finished products, which may need minor repairs before they are shipped.

-

Continuous Improvement (CI: Continuous improvement aims to increase the efficiency of operations by constantly identifying and making improvements to reduce or eliminate waste. It involves continuous improvement of processes, people, and tools.