The food manufacturing sector is large and requires many managers and professionals. Top executives organize and make decisions about production. Industrial production managers manage the day-today operations in a manufacturing plant. Marketing, public relation, sales, and community relationships managers direct marketing, promotional, as well as sales programs.

Food manufacturing jobs

New York State is home to many food production jobs. The top three occupations include bakers, food batchmakers, and packaging and filling machine operators. These occupations are responsible for less than half the state's food processing employment. Food manufacturing employment in the state increased in seven of the 10 labor markets.

An improving job market coincides with the increase in food manufacturing jobs. In February, the unemployment rate fell to 3.8%, which is the lowest in over a decade. The nondurable goods and food industries experienced the highest increase in employment, with 16,000 workers being hired.

Average wages for workers in the industry

The average wages for workers in food manufacturing range from $26,000 to $52,000 per year, with the highest paid earning an average of $52,000 per year. This range is higher for people with more experience. The lowest earners make less than $26,000 each year. The salary range for Food Factory Workers is wide, but it is generally within the range of other occupations in the manufacturing industry.

In the last few years, average wages have increased in this industry. The manufacturing industry plays a vital role in our economy. But it's not an industry that is isolated. Understanding how other economic sectors impact workers' lives is crucial.

Localities with the greatest number of workers

Food manufacturing firms concentrated in three New York State labor-market regions in 2013, the Finger Lakes and the Southern Tier. These three regions together employed almost half of the total food manufacturing workforce. These areas had high levels of food production, with the highest wages in the Hudson Valley, Southern Tier and Western New York.

Skilled labor is required in the food processing industry. Food manufacturing companies have difficulty finding skilled workers because of the lack of workers in certain areas. It is becoming increasingly difficult to find employees for distribution trucks and other lower-level posts. Career site CareersInFood.com recently found that the number of available roles in food manufacturing has increased by 12% over the past year. This includes a 37% increase over the last 24 months.

Number of workers in the industry

According to the Bureau of Labor Statistics the number of food industry workers increased by 7.200 in February. This is a more than 1% increase from January. This month marks the third consecutive month with job gains in this industry. However, it is still struggling to recover from several headwinds. The industry's unemployment has been affected by the COVID-19 virus pandemic, the labor shortage and the global recession. According to the Bureau of Labor Statistics in February, 40,700 people worked in the industry.

From 2003 to 2013, the number of food manufacturing firms in New York State increased by 8%. Employment rose in four of the 10 labor-market regions, with the highest increases in the Southern Tier & Hudson Valley.

FAQ

Can some manufacturing processes be automated?

Yes! Since ancient times, automation has been in existence. The wheel was invented by the Egyptians thousands of years ago. To help us build assembly lines, we now have robots.

Robotics is used in many manufacturing processes today. These include:

-

Automation line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots create products

Automation can be applied to manufacturing in many other ways. 3D printing, for example, allows us to create custom products without waiting for them to be made.

What kind of jobs are there in logistics?

Logistics can offer many different jobs. Some examples are:

-

Warehouse workers - They load and unload trucks and pallets.

-

Transportation drivers – These drivers drive trucks and wagons to transport goods and pick up the goods.

-

Freight handlers are people who sort and pack freight into warehouses.

-

Inventory managers – They manage the inventory in warehouses.

-

Sales representatives - They sell products to customers.

-

Logistics coordinators - They plan and organize logistics operations.

-

Purchasing agents - They buy goods and services that are necessary for company operations.

-

Customer service representatives - They answer calls and emails from customers.

-

Shippers clerks - They process shipping order and issue bills.

-

Order fillers - These people fill orders based on what has been ordered.

-

Quality control inspectors are responsible for inspecting incoming and outgoing products looking for defects.

-

Others - There are many types of jobs in logistics such as transport supervisors and cargo specialists.

What are the responsibilities of a logistic manager?

Logistics managers make sure all goods are delivered on schedule and without damage. This is done by using his/her experience and knowledge of the company's products. He/she should ensure that sufficient stock is available in order to meet customer demand.

What are the four types of manufacturing?

Manufacturing refers to the transformation of raw materials into useful products by using machines and processes. It includes many different activities like designing, building and testing, packaging, shipping and selling, as well as servicing.

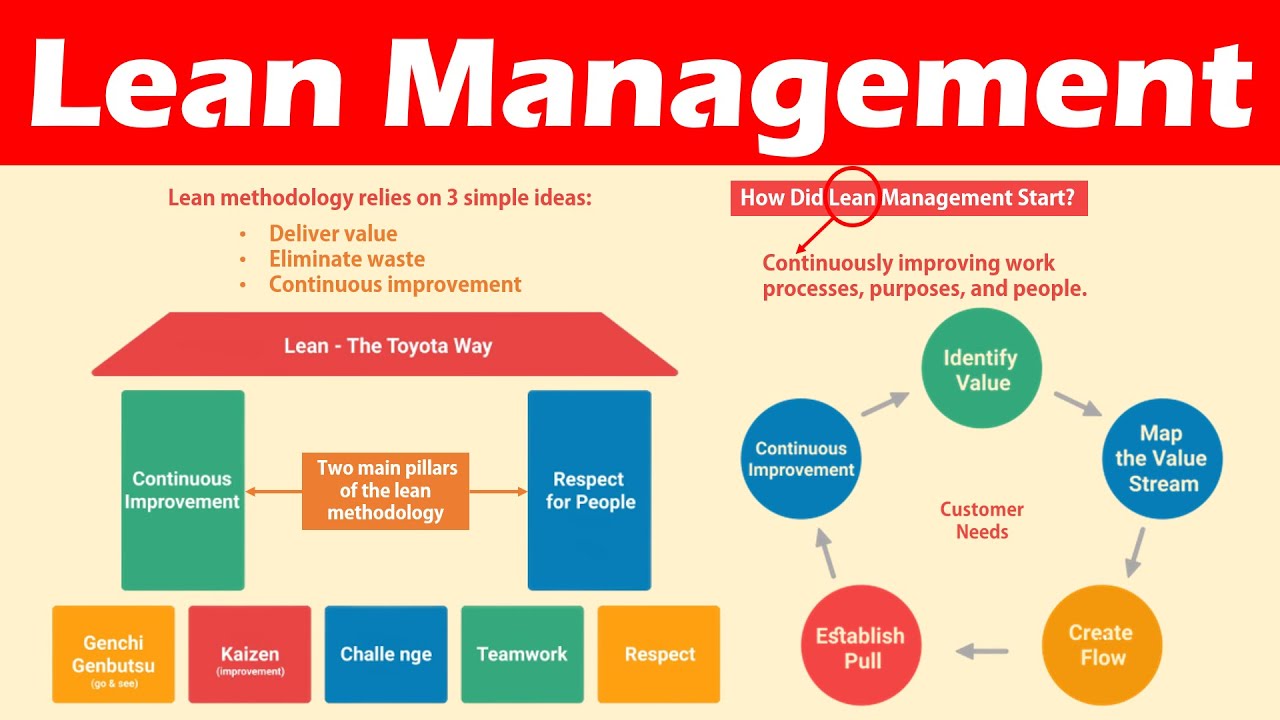

How does manufacturing avoid bottlenecks in production?

Avoiding production bottlenecks is as simple as keeping all processes running smoothly, from the time an order is received until the product ships.

This includes planning for capacity requirements as well as quality control measures.

This can be done by using continuous improvement techniques, such as Six Sigma.

Six Sigma management is a system that improves quality and reduces waste within your organization.

It focuses on eliminating variation and creating consistency in your work.

Statistics

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

External Links

How To

How to Use the 5S to Increase Productivity In Manufacturing

5S stands in for "Sort", the "Set In Order", "Standardize", or "Separate". Toyota Motor Corporation developed the 5S method in 1954. It allows companies to improve their work environment, thereby achieving greater efficiency.

The idea behind standardizing production processes is to make them repeatable and measurable. This means that tasks such as cleaning, sorting, storing, packing, and labeling are performed daily. Through these actions, workers can perform their jobs more efficiently because they know what to expect from them.

Five steps are required to implement 5S: Sort, Set In Order, Standardize. Separate. Each step has a different action and leads to higher efficiency. By sorting, for example, you make it easy to find the items later. When you arrange items, you place them together. After you have divided your inventory into groups you can store them in easy-to-reach containers. Labeling your containers will ensure that everything is correctly labeled.

Employees need to reflect on how they do their jobs. Employees need to understand the reasons they do certain jobs and determine if there is a better way. They will need to develop new skills and techniques in order for the 5S system to be implemented.

The 5S Method not only improves efficiency, but it also helps employees to be more productive and happier. They feel more motivated to work towards achieving greater efficiency as they see the results.