In the United States, chemical manufacturing is a major industry that transforms organic and inorganic raw materials into useful products. It provides materials and goods for industries that include plastics, explosives, and consumer goods. However, the chemical industry also faces many challenges. Numerous workers are at high risk for health and safety.

Chemical manufacturing is organized into two main segments: commodity chemicals and specialty chemicals. These two groups share the same infrastructure, utilities, production processes, and other resources. But the products offered by these groups are not identical. Specialty chemicals are usually designed for specific customer uses. Specialty chemicals manufacturers make some of the most expensive chemicals. Many of these are protected by patents.

While some chemicals can be made at one place, the majority of petrochemicals or commodity chemicals are produced at large-scale facilities. Rotterdam in The Netherlands and Texas are three examples of large-scale chemical facilities. Large scale chemical plants often share utilities and other infrastructures, creating economies of scale.

The United States is the second-largest chemical manufacturer in the world behind China. Statista says that the industry generates more than $4 trillion annually. About half of industry revenue is generated by the top 50 US companies.

The chemical manufacturing industry employs approximately 20 million people worldwide. The majority of these workers work in large scale facilities. A small number of them are contract or part-time workers. The industry's employment situation has been negatively affected by increased competition and technological advances.

The overall U.S. economy drives the demand for chemicals. The chemical industry is also highly regulated. Governing bodies set regulations and standards for the manufacturing process. Companies need to implement sustainable manufacturing practices. Additionally, some chemical manufacturing raw materials are dangerous to extract.

This industry is facing a difficult procurement process. Additionally, raw material costs are very high. Companies are moving their operations to areas with lower overhead in an effort to reduce costs. Finally, some companies merge or shift production to developing nations. This will lead eventually to the elimination or merging of companies.

Eighty percent of all jobs were provided by the basic chemical production segment in 2008. This group includes manufacturers of dyes, pesticides, and other material. Among the largest manufacturing employers in this segment are Dow, Pfizer, and BASF. Other major players include DuPont, Formosa Plastics, and Sinopec Group.

Large-scale production lines are generally clean. Workers are required to wear safety goggles and work in a temperature-controlled environment. Some workers, however, are replaced with advanced machines and computerized controls. These workers often work night shifts.

Chemical manufacturing plants may need to be modified to accommodate new production methods. New processes may improve accuracy and decrease labor costs. The use of nanotechnology can also improve the efficiency of chemical manufacturing. Companies will also benefit from nanotechnology in order to save energy and reduce the waste.

Other factors that affect the employment in the chemical manufacturing sector include increased foreign competition, technological advances, and concerns about safety and environmental health. Generally, the industry's employment is projected to decrease 13 percent over the next four years.

FAQ

What jobs are available in logistics?

Logistics can offer many different jobs. Here are some:

-

Warehouse workers - They load and unload trucks and pallets.

-

Transport drivers - These are people who drive trucks and trailers to transport goods or perform pick-ups.

-

Freight handlers – They sort and package freight at warehouses.

-

Inventory managers – They manage the inventory in warehouses.

-

Sales representatives - They sell products.

-

Logistics coordinators - They organize and plan logistics operations.

-

Purchasing agents – They buy goods or services necessary to run a company.

-

Customer service agents - They answer phone calls and respond to emails.

-

Shipping clerks - They process shipping orders and issue bills.

-

Order fillers – They fill orders based upon what was ordered and shipped.

-

Quality control inspectors - They check incoming and outgoing products for defects.

-

Others - There are many types of jobs in logistics such as transport supervisors and cargo specialists.

What are the main products of logistics?

Logistics are the activities involved in moving goods from point A to point B.

These include all aspects related to transport such as packaging, loading and transporting, storing, transporting, unloading and warehousing inventory management, customer service. Distribution, returns, recycling are some of the options.

Logisticians ensure that the product is delivered to the correct place, at the right time, and under safe conditions. They help companies manage their supply chain efficiency by providing information on demand forecasts, stock levels, production schedules, and availability of raw materials.

They can also track shipments in transit and monitor quality standards.

What are the differences between these four types?

Manufacturing is the process of transforming raw materials into useful products using machines and processes. Manufacturing involves many activities, including designing, building, testing and packaging, shipping, selling, service, and so on.

What are the essential elements of running a logistics firm?

To be a successful businessman in logistics, you will need many skills and knowledge. You must have good communication skills to interact effectively with your clients and suppliers. You will need to know how to interpret data and draw conclusions. You must be able and able to handle stress situations and work under pressure. To improve efficiency, you must be innovative and creative. Strong leadership qualities are essential to motivate your team and help them achieve their organizational goals.

It is also important to be efficient and well organized in order meet deadlines.

What does manufacturing mean?

Manufacturing Industries are businesses that produce products for sale. Consumers are the people who purchase these products. These companies employ many processes to achieve this purpose, such as production and distribution, retailing, management and so on. They produce goods from raw materials by using machines and other machinery. This covers all types of manufactured goods including clothing, food, building supplies and furniture, as well as electronics, tools, machinery, vehicles and pharmaceuticals.

Statistics

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

External Links

How To

How to Use lean manufacturing in the Production of Goods

Lean manufacturing is a management system that aims at increasing efficiency and reducing waste. It was developed by Taiichi Okono in Japan, during the 1970s & 1980s. TPS founder Kanji Takoda awarded him the Toyota Production System Award (TPS). Michael L. Watkins published the "The Machine That Changed the World", the first book about lean manufacturing. It was published in 1990.

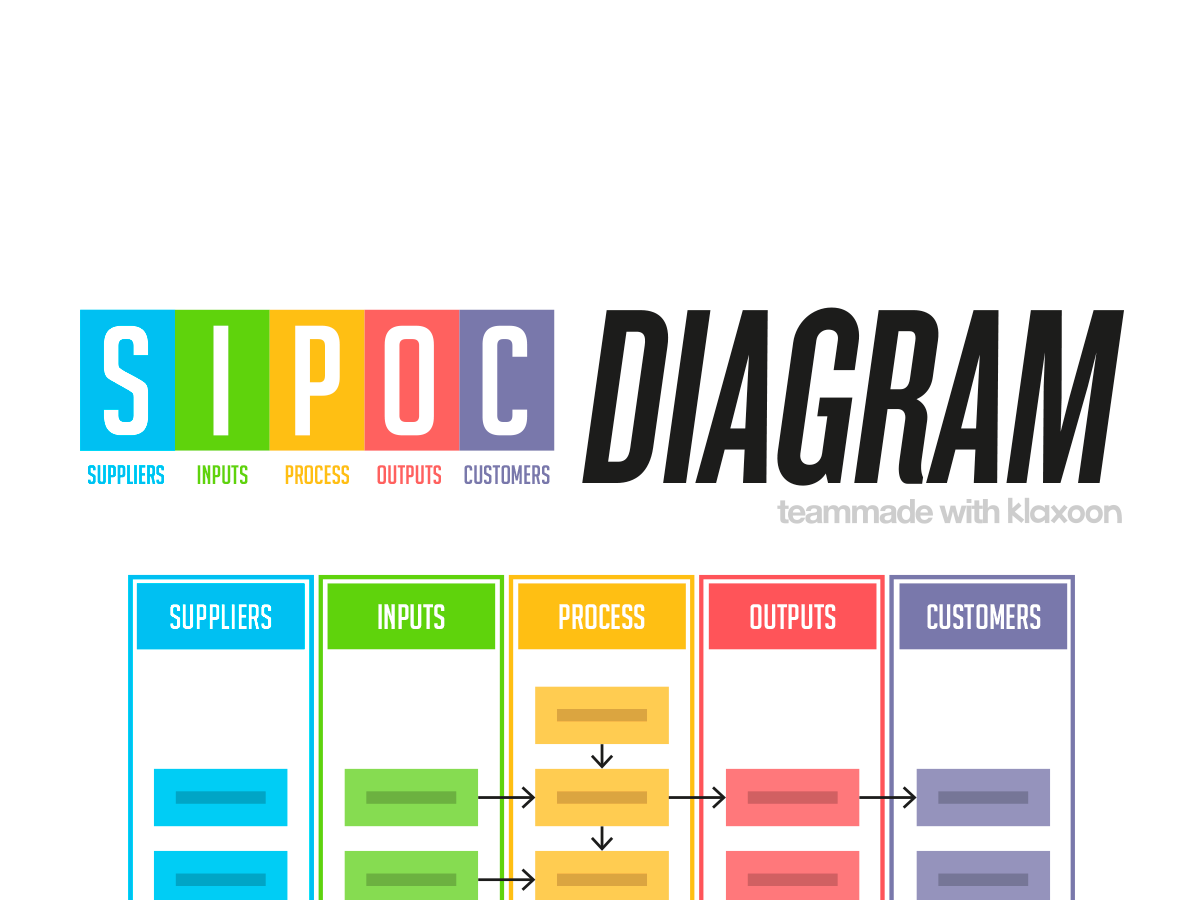

Lean manufacturing, often described as a set and practice of principles, is aimed at improving the quality, speed, cost, and efficiency of products, services, and other activities. It emphasizes the elimination and minimization of waste in the value stream. Lean manufacturing can be described as just-in–time (JIT), total productive maintenance, zero defect (TPM), or even 5S. Lean manufacturing is about eliminating activities that do not add value, such as inspection, rework, and waiting.

Lean manufacturing not only improves product quality but also reduces costs. Companies can also achieve their goals faster by reducing employee turnover. Lean Manufacturing is one of the most efficient ways to manage the entire value chains, including suppliers and customers as well distributors and retailers. Lean manufacturing can be found in many industries. Toyota's philosophy is a great example of this. It has helped to create success in automobiles as well electronics, appliances and healthcare.

Lean manufacturing is based on five principles:

-

Define Value: Identify the social value of your business and what sets you apart.

-

Reduce Waste – Eliminate all activities that don't add value throughout the supply chain.

-

Create Flow - Ensure work moves smoothly through the process without interruption.

-

Standardize and Simplify – Make processes as consistent, repeatable, and as simple as possible.

-

Building Relationships – Establish personal relationships with both external and internal stakeholders.

Lean manufacturing isn’t new, but it has seen a renewed interest since 2008 due to the global financial crisis. Many companies have adopted lean manufacturing methods to increase their marketability. Many economists believe lean manufacturing will play a major role in economic recovery.

Lean manufacturing, which has many benefits, is now a standard practice in the automotive industry. These include better customer satisfaction and lower inventory levels. They also result in lower operating costs.

The principles of lean manufacturing can be applied in almost any area of an organization. However, it is particularly useful when applied to the production side of an organization because it ensures that all steps in the value chain are efficient and effective.

There are three types of lean manufacturing.

-

Just-in-Time Manufacturing (JIT): This type of lean manufacturing is commonly referred to as "pull systems." JIT is a process in which components can be assembled at the point they are needed, instead of being made ahead of time. This approach reduces lead time, increases availability and reduces inventory.

-

Zero Defects Manufacturing (ZDM),: ZDM is a system that ensures no defective units are left the manufacturing facility. You should repair any part that needs to be repaired during an assembly line. This applies to finished products, which may need minor repairs before they are shipped.

-

Continuous Improvement (CI),: Continuous improvement aims improve the efficiency and effectiveness of operations by continuously identifying issues and making changes to reduce waste. Continuous Improvement (CI) involves continuous improvement in processes, people, tools, and infrastructure.