There is a great demand for logistics positions in Jacksonville, Florida. These jobs are vital in the delivery and shipment of goods from the factory floor to customers' doorsteps. You can expect a high salary if you have the right skills. Here are some tips and techniques to help you get the job you want.

The most obvious first step is to set up a profile on Monster. This will allow you to receive job alerts for free and a personalized listing of relevant listings. You will also receive expert advice. An experienced recruiter will explain the benefits of working in a particular company to you, so you can be ready to take on the competition. Having a solid handle on your qualifications and qualifications for the job you want will put you on the fast track to success.

Consider a paid internship while you're at work. Working for pros is a great way to learn, and it costs only $10 to $15 per hour. You'll also gain practical experience that you can use in your job search. This is the best type of training you could get. This training comes with a reward: a swag bag filled with goodies.

The most important thing to remember is that you do not have to be a logistics expert to land the job you want. There are many entry-level opportunities for logistics professionals who have no technical skills. Vaco, Penske and others offer their employees traditional working environments. Other companies provide flexibility. Whatever route you decide to take, you'll likely find a suitable position in the Jacksonville, FL area.

Scott Logistics Corp. and Quaker Transportation are two of the best companies in the region to get you started. Both 3PLs (third-party logistics providers) will allow you to experience the perks of working at a large company. From there, you'll be able to decide which one suits you the best. It's not fair to lose out on a lucrative job because you don't know how to find it.

FAQ

Why is logistics important in manufacturing

Logistics are an integral part any business. They can help you achieve great success by helping you manage product flow from raw material to finished goods.

Logistics play a key role in reducing expenses and increasing efficiency.

How important is automation in manufacturing?

Automation is essential for both manufacturers and service providers. Automation allows them to deliver services quicker and more efficiently. They can also reduce their costs by reducing human error and improving productivity.

Why automate your factory?

Automation has become increasingly important in modern warehousing. E-commerce has increased the demand for quicker delivery times and more efficient processes.

Warehouses must be able to quickly adapt to changing demands. To do so, they must invest heavily in technology. Automating warehouses has many benefits. Here are some reasons why it's worth investing in automation:

-

Increases throughput/productivity

-

Reduces errors

-

Increases accuracy

-

Safety Boosts

-

Eliminates bottlenecks

-

Companies can scale more easily

-

It makes workers more efficient

-

It gives visibility to everything that happens inside the warehouse

-

Enhances customer experience

-

Improves employee satisfaction

-

Reducing downtime and increasing uptime

-

This ensures that quality products are delivered promptly

-

Human error can be eliminated

-

Assure compliance with regulations

Statistics

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

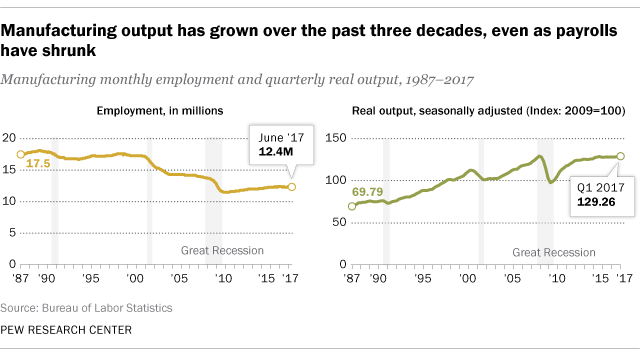

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

External Links

How To

Six Sigma in Manufacturing

Six Sigma refers to "the application and control of statistical processes (SPC) techniques in order to achieve continuous improvement." Motorola's Quality Improvement Department created Six Sigma at their Tokyo plant, Japan in 1986. Six Sigma is a method to improve quality through standardization and elimination of defects. In recent years, many companies have adopted this method because they believe there is no such thing as perfect products or services. Six Sigma aims to reduce variation in the production's mean value. This means that you can take a sample from your product and then compare its performance to the average to find out how often the process differs from the norm. If this deviation is too big, you know something needs fixing.

Understanding how your business' variability is a key step towards Six Sigma implementation is the first. Once you have this understanding, you will need to identify sources and causes of variation. You'll also want to determine whether these variations are random or systematic. Random variations happen when people make errors; systematic variations are caused externally. Random variations would include, for example, the failure of some widgets to fall from the assembly line. You might notice that your widgets always fall apart at the same place every time you put them together.

After identifying the problem areas, you will need to devise solutions. The solution could involve changing how you do things, or redesigning your entire process. You should then test the changes again after they have been implemented. If they don’t work, you’ll need to go back and rework the plan.