You have reached the right place if you are searching for a job within the manufacturing sector. The manufacturing industry is constantly improving and changing with the advent of new technology. Even if you don't have much experience, you don’t necessarily have to have a college education to enter this field. Major manufacturing firms offer training on-the-job to help you acquire the skills that you need to succeed. You can read on to find out about the jobs in manufacturing near you.

Description of the job for a machine operator

If you are looking for a job as a machine operator, you can use a job description sample to get started. Next, modify the job description sample to meet your specific needs. You can also check out Monster's job listings for more ideas. Your job description's opening paragraph is your chance for prospective candidates to get to know your company. In two to three sentences, you should tell them what makes your company unique and why you are the best fit for this position.

Machine operators perform a variety of tasks, including putting parts into machines, loading them, and operating them. They are responsible for performing routine maintenance checks, and following safety regulations. They might be expected to supervise other operators and maintain equipment as part of a group. Other duties may also be included in some job descriptions, such as helping warehouse operations. After their tasks are completed, they must inspect and clean the equipment.

For a manager of plastic injection mould operations, you will need the following skills

You will need to be able to manage the entire process, from start to finish. This role involves the creation of new injection molding machines and coordination of the processing of injection moulding tooling. This position requires the candidate to be familiar with managing large projects and building relationships with customers. They also need to coordinate engineering changes for existing programs. They must also be capable of directing the activities of the plant in order to maximize its efficiency.

A job description should detail the responsibilities of the position and its benefits. Make sure to mention operator credentials and technical safety. Avoid abbreviations. Use action-oriented languages. It is important to include information about the company's culture. These details will attract qualified candidates. Include a description of the employer and a picture. For quality candidates to apply, it is important that your company has a positive image and culture.

Description of the job for an assembly worker

Assemble products in a production line. Assign to a particular part of the product, workers on assembly lines must give the finished product to the next worker. They control the inventory of products and ensure that the final product is of high quality. Assembling products safely is important, and assembly line workers must be knowledgeable about health and safety practices. These workers must also work in a hygienic environment.

This job requires excellent hand-eye coordination as well as physical fitness. Assemblers may be exposed to hazardous fumes, chemicals, and other elements. They must also be vigilant about machinery and tools. Inflicting serious injuries on the job can be caused by negligence. This job requires fast thinking, good hand-eye coordination, and excellent attention to detail. Assemblers need to be able and able talk with other workers in the assembly station. They must also report malfunctions or problems with machinery.

Manufacturing career opportunities

If you're in search of a new career, manufacturing is the perfect place to start. Manufacturing jobs can include program management, design engineering, quality control, and production. As you move up the ranks, you may become a quality control inspector and even lead a team. These roles are often rewarding, and there is a lot to be done. The industry offers many opportunities even for those with little experience. Manufacturing is the perfect career choice for recent graduates and those looking to increase their work experience or change industries.

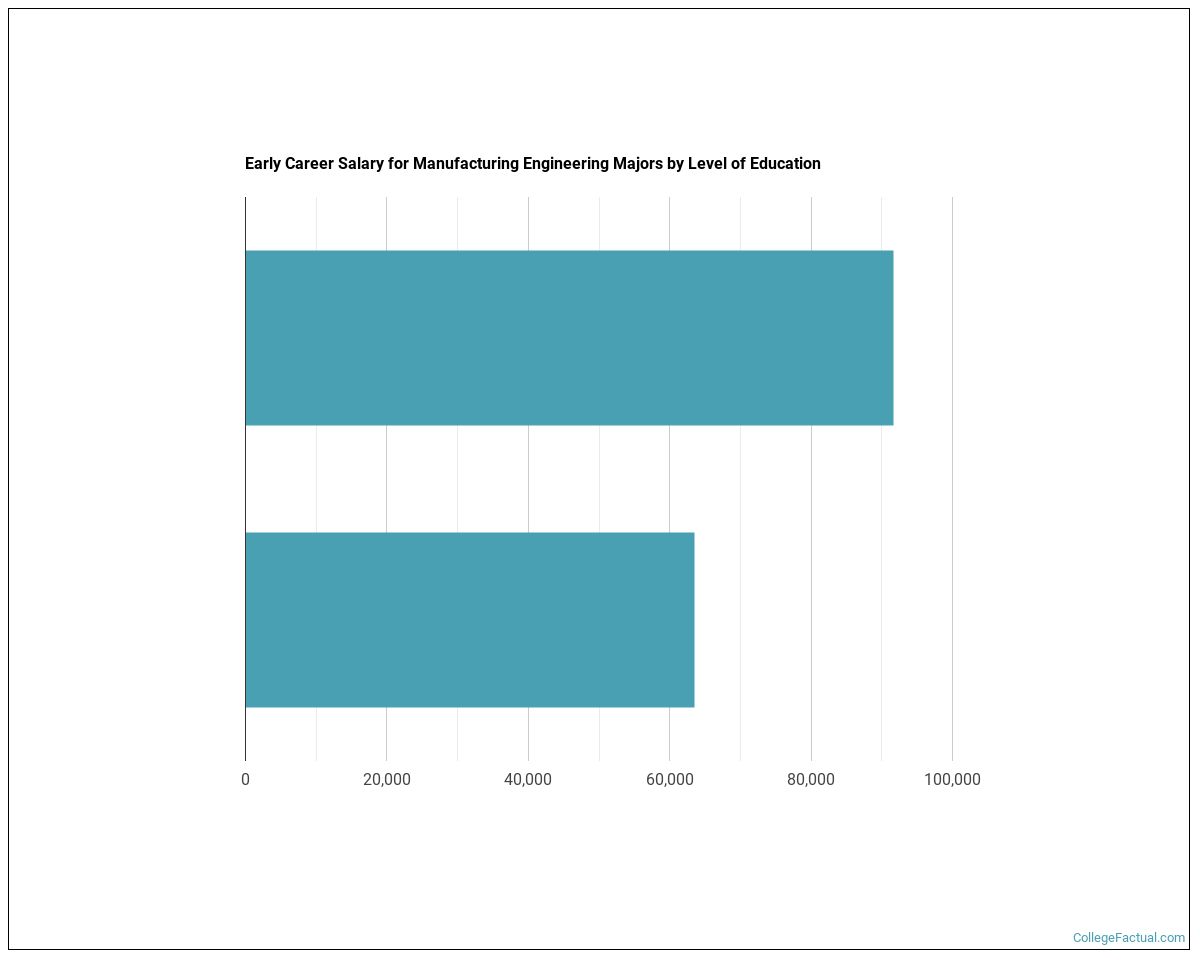

Manufacturing careers can offer high-paying jobs and a wide variety of postsecondary education options. You can use the skills you have gained in this field to get many opportunities after graduation in a variety different fields. To advance your career, you could even apply to an apprenticeship program or enroll in a college for two- or four years. There are so many possibilities. However, you should keep in mind that careers in manufacturing are not for everyone.

FAQ

What does it mean to be a manufacturer?

Manufacturing Industries refers to businesses that manufacture products. Consumers are people who purchase these goods. To accomplish this goal, these companies employ a range of processes including distribution, sales, management, and production. They make goods from raw materials with machines and other equipment. This includes all types and varieties of manufactured goods, such as food items, clothings, building supplies, furnitures, toys, electronics tools, machinery vehicles, pharmaceuticals medical devices, chemicals, among others.

What are the requirements to start a logistics business?

It takes a lot of skills and knowledge to run a successful logistics business. For clients and suppliers to be successful, you need to have excellent communication skills. You must be able analyze data and draw out conclusions. You will need to be able handle pressure well and work in stressful situations. To improve efficiency, you must be innovative and creative. To motivate and guide your team towards reaching organizational goals, you must have strong leadership skills.

To meet tight deadlines, you must also be efficient and organized.

What is the difference between manufacturing and logistics

Manufacturing is the production of goods using raw materials. Logistics is the management of all aspects of supply chain activities, including procurement, production planning, distribution, warehousing, inventory control, transportation, and customer service. As a broad term, manufacturing and logistics often refer to both the creation and delivery of products.

Can we automate some parts of manufacturing?

Yes! Yes. The Egyptians created the wheel thousands years ago. Today, robots assist in the assembly of lines.

Robotics is used in many manufacturing processes today. These include:

-

Line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots that produce products

Automation can be applied to manufacturing in many other ways. 3D printing, for example, allows us to create custom products without waiting for them to be made.

Statistics

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

External Links

How To

How to Use the Just-In-Time Method in Production

Just-in time (JIT), is a process that reduces costs and increases efficiency in business operations. It's the process of obtaining the right amount and timing of resources when you need them. This means that you only pay the amount you actually use. Frederick Taylor was the first to coin this term. He developed it while working as a foreman during the early 1900s. He noticed that workers were often paid overtime when they had to work late. He decided to ensure workers have enough time to do their jobs before starting work to improve productivity.

The idea behind JIT is that you should plan ahead and have everything ready so you don't waste money. It is important to look at your entire project from beginning to end and ensure that you have enough resources to handle any issues that may arise. If you anticipate that there might be problems, you'll have enough people and equipment to fix them. This will prevent you from spending extra money on unnecessary things.

There are different types of JIT methods:

-

Demand-driven: This type of JIT allows you to order the parts/materials required for your project on a regular basis. This will allow to track how much material has been used up. This will allow you to calculate how long it will take to make more.

-

Inventory-based: This type allows you to stock the materials needed for your projects ahead of time. This allows you to predict how much you can expect to sell.

-

Project-driven: This method allows you to set aside enough funds for your project. If you know the amount you require, you can buy the materials you need.

-

Resource-based JIT is the most widespread form. You assign certain resources based off demand. For instance, if you have a lot of orders coming in, you'll assign more people to handle them. If you don't have many orders, you'll assign fewer people to handle the workload.

-

Cost-based: This is a similar approach to resource-based but you are not only concerned with how many people you have, but also how much each one costs.

-

Price-based: This approach is very similar to the cost-based method except that you don't look at individual workers costs but the total cost of the company.

-

Material-based is an alternative to cost-based. Instead of looking at the total cost in the company, this method focuses on the average amount of raw materials that you consume.

-

Time-based JIT: This is another variant of resource-based JIT. Instead of focusing on how much each employee costs, you focus on how long it takes to complete the project.

-

Quality-based JIT - This is another form of resource-based JIT. Instead of thinking about how much each employee costs or how long it takes to manufacture something, you think about how good the quality of your product is.

-

Value-based: This is one of the newest forms of JIT. This is where you don't care about how the products perform or whether they meet customers' expectations. Instead, your focus is on the value you bring to the market.

-

Stock-based: This inventory-based approach focuses on how many items are being produced at any one time. It's used when you want to maximize production while minimizing inventory.

-

Just-intime (JIT), planning is a combination JIT management and supply chain management. It is the process that schedules the delivery of components within a short time of their order. It's important because it reduces lead times and increases throughput.