The state in which you reside will determine how much your average engineer salary is. In the United States, the highest paying state is Washington, followed by New York and California. When moving to a new country, it is important that you consider the cost per capita. As an example, a salary of $96,640 may not be sufficient to pay all your living expenses. You should consider your expenses before you apply to a new position.

Electrical engineers earn a median salary of $96,640

According to the U.S. Bureau of Labor Statistics (USBoLS), the average annual salary of an electric engineer is $96,640. This number may differ from one state to another. Salaries can also vary considerably within industry sectors. Electrical engineers are most highly paid in retail trade. Educational services is the least lucrative. However, there are some important factors to consider when determining the average salary for an electrical engineer. Below is an overview of the average salary for different types and levels of electrical engineers.

Electricians are responsible to design and develop electrical equipment. These engineers also oversee the installation and manufacturing of these products. This statistic includes salaries of all types, but not Computer Hardware Engineers. Computer Hardware Engineers are those who create computers. According to the Bureau of Labor Statistics, employment of these professionals will grow by 7 percent by 2026. Although most electricians will be working in an office, they may travel to other types of locations for field work.

Biomedical engineering professionals earn an average salary of $89130

Biomedical engineer combine their engineering knowledge with knowledge about the human body to design medical devices. Their knowledge of biomechanics allows them to understand the interaction between different medical products and the body. This knowledge is useful for creating artificial organs and medical devices as well as diagnostic tools.

Biomedical engineers must be able to communicate well and not only apply engineering principles to medical procedures. They are expected to communicate with other health care professionals, present research results and publish scientific papers. Moreover, they must be proficient in advanced mathematics.

The median salary for mechanical engineers is $91,352.

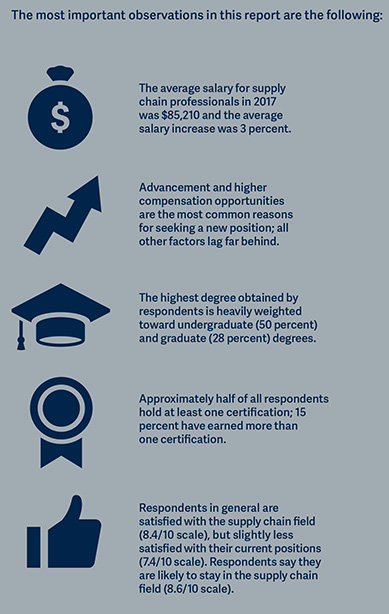

Many factors affect the salary of a mechanic engineer. Salaries can differ by industry and location. According to ASME members' 2017 Salary Survey, those in the Northeast and Southwest have higher salaries than others. The Midwest earns less than those who work there.

Mechanical engineers can earn salaries ranging from $91,352 up to $137,028. The average engineer's salary is $91,352, but the top sixth earn more than the median. The average income for those with less then two years experience is $72,400. But, those with more experience than two years can earn up to $150,000.

Agricultural engineers earn a median salary of $89,130

Agricultural engineers work in agricultural settings to help solve problems related to environmental and power supplies. They are also involved in designing and overseeing construction. This profession requires advanced engineering skills and knowledge of the sciences, including biology and math. Their salaries are comparable with other related occupations in America. They typically make less than naval architects or locomotive engineers. The outlook for agricultural engineers looks positive. Between 2016 and 2026, there will be a 7.4% increase in employment.

The median salary for American agricultural engineers is $89130. The highest paid individuals make more than $110,000. The median salary for agricultural engineers varies by location. The highest-paid cities for agricultural engineers include Santa Clara, San Francisco, and Bolinas.

Environmental engineers earn a median salary of $87,620

Engineers who are environmental engineers help to protect the environment and implement solutions to minimize harmful effects. They might work in different fields or collaborate with other engineers like urban planners and construction managers. They have a broad education in biology and chemistry as well as data analysis. They help organizations comply with regulations and also have a good understanding of environmental law.

As a result, environmental engineers have to be versatile and able to adjust to changing technologies and best practices. They should also be analytically skilled and able to work in a team. They need to be problem solvers and positive.

FAQ

Why is logistics so important in manufacturing?

Logistics are essential to any business. They help you achieve great results by helping you manage all aspects of product flow, from raw materials to finished goods.

Logistics also play a major role in reducing costs and increasing efficiency.

What is manufacturing and logistics?

Manufacturing is the production of goods using raw materials. Logistics manages all aspects of the supply chain, including procurement, production planning and distribution, inventory control, transportation, customer service, and transport. Manufacturing and logistics are often considered together as a broader term that encompasses both the process of creating products and delivering them to customers.

How can excess manufacturing production be reduced?

The key to reducing overproduction lies in developing better ways to manage inventory. This would reduce the time spent on unproductive activities like purchasing, storing and maintaining excess stock. By doing this, we could free up resources for other productive tasks.

This can be done by using a Kanban system. A Kanbanboard is a visual tool that allows you to keep track of the work being done. Kanban systems are where work items travel through a series of states until reaching their final destination. Each state represents a different priority level.

For instance, when work moves from one stage to another, the current task is complete enough to be moved to the next stage. It is possible to keep a task in the beginning stages until it gets to the end.

This keeps work moving and ensures no work is lost. A Kanban board allows managers to monitor how much work is being completed at any given moment. This data allows them adjust their workflow based upon real-time data.

Another way to control inventory levels is to implement lean manufacturing. Lean manufacturing focuses on eliminating waste throughout the entire production chain. Any product that isn't adding value can be considered waste. Some common types of waste include:

-

Overproduction

-

Inventory

-

Packaging that is not necessary

-

Exceed materials

By implementing these ideas, manufacturers can improve efficiency and cut costs.

Is automation important in manufacturing?

Automation is important not only for manufacturers but also for service providers. They can provide services more quickly and efficiently thanks to automation. It helps them to lower costs by reducing human errors, and improving productivity.

What is the role and responsibility of a Production Planner?

Production planners make sure that every aspect of the project is delivered on-time, within budget, and within schedule. They ensure that the product or service is of high quality and meets client requirements.

Statistics

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

External Links

How To

How to Use lean manufacturing in the Production of Goods

Lean manufacturing (or lean manufacturing) is a style of management that aims to increase efficiency, reduce waste and improve performance through continuous improvement. It was developed by Taiichi Okono in Japan, during the 1970s & 1980s. TPS founder Kanji Takoda awarded him the Toyota Production System Award (TPS). The first book published on lean manufacturing was titled "The Machine That Changed the World" written by Michael L. Watkins and published in 1990.

Lean manufacturing is often described as a set if principles that help improve the quality and speed of products and services. It emphasizes the elimination and minimization of waste in the value stream. Lean manufacturing is also known as just in time (JIT), zero defect total productive maintenance(TPM), and five-star (S). Lean manufacturing focuses on eliminating non-value-added activities such as rework, inspection, and waiting.

Lean manufacturing can help companies improve their product quality and reduce costs. Additionally, it helps them achieve their goals more quickly and reduces employee turnover. Lean manufacturing is a great way to manage the entire value chain including customers, suppliers, distributors and retailers as well as employees. Lean manufacturing can be found in many industries. Toyota's philosophy is the foundation of its success in automotives, electronics and appliances, healthcare, chemical engineers, aerospace, paper and food, among other industries.

Five fundamental principles underlie lean manufacturing.

-

Define Value - Determine the value that your business brings to society. Also, identify what sets you apart from your competitors.

-

Reduce waste - Stop any activity that isn't adding value to the supply chains.

-

Create Flow – Ensure that work flows smoothly throughout the process.

-

Standardize and Simplify – Make processes as consistent, repeatable, and as simple as possible.

-

Building Relationships – Establish personal relationships with both external and internal stakeholders.

Lean manufacturing isn’t new, but it has seen a renewed interest since 2008 due to the global financial crisis. Many businesses are now using lean manufacturing to improve their competitiveness. In fact, some economists believe that lean manufacturing will be an important factor in economic recovery.

Lean manufacturing is becoming a popular practice in automotive. It has many advantages. These benefits include increased customer satisfaction, reduced inventory levels and lower operating costs.

Lean manufacturing can be applied to almost every aspect of an organization. This is because it ensures efficiency and effectiveness in all stages of the value chain.

There are three types of lean manufacturing.

-

Just-in-Time Manufacturing (JIT): This type of lean manufacturing is commonly referred to as "pull systems." JIT means that components are assembled at the time of use and not manufactured in advance. This approach reduces lead time, increases availability and reduces inventory.

-

Zero Defects Manufacturing, (ZDM): ZDM is focused on ensuring that no defective products leave the manufacturing facility. It is better to repair a part than have it removed from the production line if it needs to be fixed. This applies to finished products, which may need minor repairs before they are shipped.

-

Continuous Improvement (CI): CI aims to improve the efficiency of operations by continuously identifying problems and making changes in order to eliminate or minimize waste. Continuous improvement refers to continuous improvement of processes as well people and tools.