What is supply chains management? Supply chain management is a cross-functional process that manages relationships across the entire supply chain. Supply chain management helps improve business performance by improving operational and financial performance. This article will outline the basic concepts of supply-chain management and how they can benefit your organization. Let's start! What is supply chains management? Why is supply management so important? These are just a few ways it can help your business.

Management of relationships within the supply chain is called supply chain management.

When selling products, companies need to know how to source raw materials and produce parts. The physical flow of goods begins with a supplier and moves forward through various steps to a manufacturer, distributor, retailer, and finally, the end consumer. Certain supply chains skip certain steps, but the physical items must be moved from one point to another, be stored for a period of time, and be delivered to the end customer. This is a process that requires organization and planning.

Integrating all business functions is essential for successful supply chain management. For example, vendors and suppliers must have clear communications. Information sharing allows each party to know what to expect, decrease costs, and improve the quality of their work. In addition, collaborative planning improves communication and collaboration across the supply chain, which ultimately benefits both parties. The customer should be aware of the company's operational process, and the vendor must know how to deliver emergency materials. Perishable goods are more sensitive than usual.

It is a cross-functional business process

Many factors are important to consider when it comes down to a company’s supply chain. For a supply chain to be successful, suppliers need to be able delivery goods on time. That is why it is so important to coordinate. Follow these steps to avoid any problems. Companies will be able to improve their efficiency and save money by following these steps.

In addition to understanding the interdependencies of the supply chain, management needs to work toward increasing the profitability of the entire system. Each party should receive equal benefits from process improvements. However, it is important for management to establish guidelines on how rewards will be divided. If the process is not based on a common measurement method, some parties may not be able to see the benefits. It may be deemed uneffective if the value cannot be captured.

It reduces operating cost

Streamlining ordering processes can be one of the best ways reduce operating costs. By using one software system for all of your requisitions, your employees will be less likely to get confused or order too much of a product. A process for approval can be set up to limit the quantity of goods ordered. This will help to lower operating costs. A streamlined software system can help you avoid confusion and errors, monitor your inventory and order only what you need. It will also allow you to stop shipments being made if you are not required.

An alternative method to reduce operating expenses is improving communication among warehouse employees. You should first examine your current workflow and identify any bottlenecks. Reduce transportation costs by consolidating shipments or using dedicated transportation services. This will reduce your operating expenses by a substantial amount. This will help you not only lower your transport costs but also speed up the delivery of your products.

It improves financial position

A business's financial performance can be improved by supply chain management in many ways. Supply chain management can help reduce production costs and maximize the benefits of variable cost. Controlling costs can increase profit margins. Another major benefit is an increase in cash flow. A faster delivery of products to the customer can help it invoice its customers earlier, reducing the need to purchase expensive building space. Additionally, a better supply network reduces the costs of fixed assets.

The Statement of shareholders' equity (SSE) summarizes the ownership percentage of a company. A firm can improve its supply chain to increase its after-tax cashflow by around 8.5%. A company can lower its costs up to 10% by improving its supply chain performance and increase customer satisfaction. If supply chain management improves financial performance, a company can realize operational efficiencies that lead to higher profits.

FAQ

What is the responsibility for a logistics manager

Logistics managers ensure that goods arrive on time and are unharmed. This is accomplished by using the experience and knowledge gained from working with company products. He/she should also ensure enough stock is available to meet demand.

Why automate your warehouse

Modern warehousing is becoming more automated. E-commerce has brought increased demand for more efficient and quicker delivery times.

Warehouses need to adapt quickly to meet changing needs. In order to do this, they need to invest in technology. Automation warehouses can bring many benefits. Here are some reasons why it's worth investing in automation:

-

Increases throughput/productivity

-

Reduces errors

-

Improves accuracy

-

Safety increases

-

Eliminates bottlenecks

-

This allows companies to scale easily

-

This makes workers more productive

-

The warehouse can be viewed from all angles.

-

Enhances customer experience

-

Improves employee satisfaction

-

Reduces downtime and improves uptime

-

You can be sure that high-quality products will arrive on time

-

Eliminates human error

-

Helps ensure compliance with regulations

What is the role of a manager in manufacturing?

A manufacturing manager has to ensure that all manufacturing processes work efficiently and effectively. They should also be aware and responsive to any company problems.

They must also be able to communicate with sales and marketing departments.

They should also be aware of the latest trends in their industry and be able to use this information to help improve productivity and efficiency.

Is it possible to automate certain parts of manufacturing

Yes! Automation has been around since ancient times. The wheel was invented by the Egyptians thousands of years ago. Today, robots assist in the assembly of lines.

Actually, robotics can be used in manufacturing for many purposes. These include:

-

Automated assembly line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots that create products

Automation can be applied to manufacturing in many other ways. For example, 3D printing allows us to make custom products without having to wait for weeks or months to get them manufactured.

Do we need to know about Manufacturing Processes before learning about Logistics?

No. You don't have to know about manufacturing processes before learning about logistics. It is important to know about the manufacturing processes in order to understand how logistics works.

Why is logistics so important in manufacturing?

Logistics are an essential component of any business. They enable you to achieve outstanding results by helping manage product flow from raw materials through to finished goods.

Logistics also play a major role in reducing costs and increasing efficiency.

What does manufacturing industry mean?

Manufacturing Industries refers to businesses that manufacture products. Consumers are those who purchase these products. These companies use a variety processes such as distribution, retailing and management to accomplish their purpose. They create goods from raw materials, using machines and various other equipment. This includes all types and varieties of manufactured goods, such as food items, clothings, building supplies, furnitures, toys, electronics tools, machinery vehicles, pharmaceuticals medical devices, chemicals, among others.

Statistics

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

External Links

How To

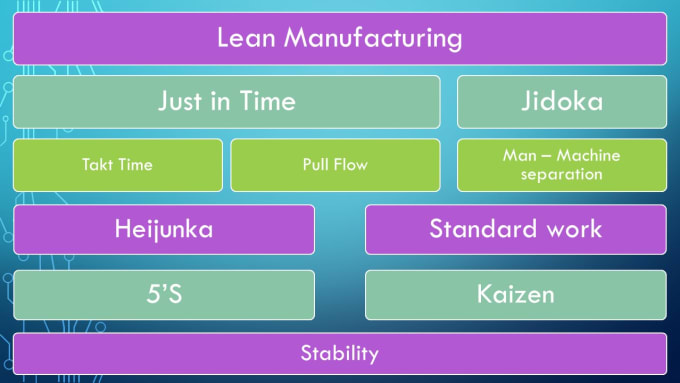

How to Use Just-In-Time Production

Just-in-time is a way to cut costs and increase efficiency in business processes. This is where you have the right resources at the right time. This means that only what you use is charged to your account. Frederick Taylor developed the concept while working as foreman in early 1900s. After observing how workers were paid overtime for late work, he realized that overtime was a common practice. He then concluded that if he could ensure that workers had enough time to do their job before starting to work, this would improve productivity.

JIT is an acronym that means you need to plan ahead so you don’t waste your money. You should also look at the entire project from start to finish and make sure that you have sufficient resources available to deal with any problems that arise during the course of your project. If you anticipate that there might be problems, you'll have enough people and equipment to fix them. This will prevent you from spending extra money on unnecessary things.

There are different types of JIT methods:

-

Demand-driven: This is a type of JIT where you order the parts/materials needed for your project regularly. This will enable you to keep track of how much material is left after you use it. This will allow to you estimate the time it will take for more to be produced.

-

Inventory-based : You can stock the materials you need in advance. This allows you to forecast how much you will sell.

-

Project-driven: This method allows you to set aside enough funds for your project. You will be able to purchase the right amount of materials if you know what you need.

-

Resource-based JIT: This is the most popular form of JIT. You allocate resources based on the demand. You might assign more people to help with orders if there are many. If you don't receive many orders, then you'll assign fewer employees to handle the load.

-

Cost-based: This is a similar approach to resource-based but you are not only concerned with how many people you have, but also how much each one costs.

-

Price-based pricing: This is similar in concept to cost-based but instead you look at how much each worker costs, it looks at the overall company's price.

-

Material-based: This is quite similar to cost-based, but instead of looking at the total cost of the company, you're concerned with how much raw materials you spend on average.

-

Time-based: Another variation of resource-based JIT. Instead of worrying about how much each worker costs, you can focus on how long the project takes.

-

Quality-based JIT: Another variation on resource-based JIT. Instead of thinking about how much each employee costs or how long it takes to manufacture something, you think about how good the quality of your product is.

-

Value-based JIT : This is the newest type of JIT. In this case, you're not concerned with how well the products perform or whether they meet customer expectations. Instead, your focus is on the value you bring to the market.

-

Stock-based: This is an inventory-based method that focuses on the actual number of items being produced at any given time. It's used when you want to maximize production while minimizing inventory.

-

Just-intime (JIT), planning is a combination JIT management and supply chain management. It refers to the process of scheduling the delivery of components as soon as they are ordered. It's important because it reduces lead times and increases throughput.