Global supply-chain management is the process of distributing goods and services within a global company's network. The principle behind this concept is to maximize profit, while minimizing waste. This distribution method offers many benefits, but there are some downsides. Let's explore some of these issues. Learn more about global supply chains management. We'll also cover some of those challenges that global supply chains can present.

Resilience

An effective global supply manager must have a strategy to promote resilience. The resilience of the supply chain can be strengthened by redesigning the supply chain, creating redundancies, and implementing multiple sourcing. Supply chains may appear rigid at first, but they can evolve with creativity, innovation, and constant vigilance. Cin7 is an inventory management software company that has provided various educational materials as well as advice to its customers.

Information sharing

Even though it might seem confusing, information sharing is essential to the survival and growth of companies. This study examines how information can be shared to benefit all parties involved in a supply chain. Information sharing offers many benefits, which may vary depending on the type of information. In general, the value of information varies depending on the parties involved. Here are some examples of information that could benefit a supply-chain.

Quality management

Quality issues are an essential part of any supply-chain. It is crucial for companies to ensure product quality. However it is equally important that secondary issues are addressed and supply chain risk managed. This article will address the role of quality in global supply chain management. It will also reveal how inefficient business systems can be made to fail this challenge. Let's discuss how companies can overcome this challenge and implement more effective quality control practices.

Logistics links

The business's needs change with the changing demands and preferences of consumers. The global supply chain is a complex web of suppliers, individuals, and companies that works together to deliver goods on time and to the right place. Logistics plays a crucial role in global supply chains management. This helps companies to reduce costs and improve performance. Supply chains encompass vendors, suppliers, producers, warehouses and transportation companies as well as retailers.

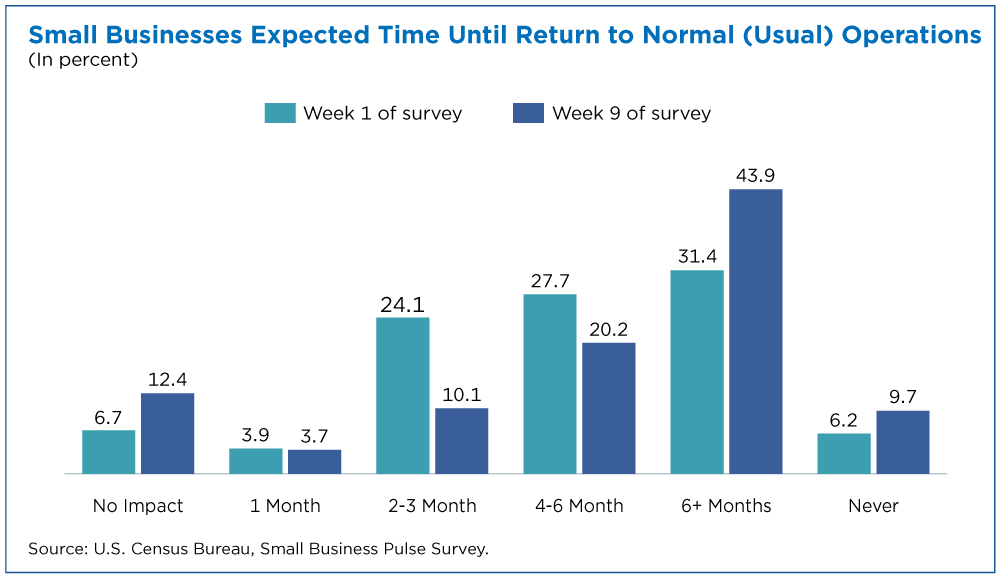

Pandemic of COVID-19

Global supply chain management is essential due to the massive spread of COVID-19. To respond to emergencies, global supply chains are critical. They ensure that essential supplies are available in a timely manner. However, the global supply network has been constrained by global economic uncertainty and the ongoing Chinese lockdown. This pandemic is testing supply chain flexibility and resilience. This crisis will bring about a new set of challenges for companies. Companies will not only be judged on their responses, but also their corporate values.

Impact on the economy

The global economy is dependent on the management of its supply chains. As more manufacturers switch to JIT (just-in-time) production, they are increasingly dependent on a single source for vital supplies. JIT production models come with a major drawback. They make it more difficult for companies to disrupt their supply chains. According to a recent survey, almost half of executives plan on removing some production from China while one-third intend to de-emphasize JIT Manufacturing.

Career opportunities

Global supply chain managers are responsible for overseeing all aspects related to a business’s international procurement strategy. They coordinate with suppliers to ensure high quality products and oversee inventory logistics. They keep track of the supply chain performance, analyze data and make recommendations. This role also requires a great deal of collaboration with other departments in a company. This list contains some career options. They all offer valuable career opportunities.

FAQ

What are the 7 Rs of logistics.

The acronym "7R's" of Logistics stands for seven principles that underpin logistics management. It was developed by the International Association of Business Logisticians (IABL) and published in 2004 as part of its "Seven Principles of Logistics Management" series.

The following letters make up the acronym:

-

Responsible – ensure that all actions are legal and don't cause harm to anyone else.

-

Reliable - You can have confidence that you will fulfill your promises.

-

Reasonable - make sure you use your resources well and don't waste them.

-

Realistic - consider all aspects of operations, including cost-effectiveness and environmental impact.

-

Respectful - show respect and treat others fairly and fairly

-

Be resourceful: Look for opportunities to save money or increase productivity.

-

Recognizable is a company that provides customers with value-added solutions.

What skills is required for a production planner?

To become a successful production planner, you need to be organized, flexible, and able to multitask. Communication skills are essential to ensure that you can communicate effectively with clients, colleagues, and customers.

Are there ways to automate parts of manufacturing?

Yes! Yes. The Egyptians invented the wheel thousands of years ago. To help us build assembly lines, we now have robots.

Actually, robotics can be used in manufacturing for many purposes. They include:

-

Automation line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots create products

Manufacturing can also be automated in many other ways. 3D printing makes it possible to produce custom products in a matter of days or weeks.

Are there any Manufacturing Processes that we should know before we can learn about Logistics?

No. No. It is important to know about the manufacturing processes in order to understand how logistics works.

How can efficiency in manufacturing be improved?

The first step is to identify the most important factors affecting production time. The next step is to identify the most important factors that affect production time. If you don't know where to start, then think about which factor(s) have the biggest impact on production time. Once you have identified the factors, then try to find solutions.

Statistics

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

External Links

How To

How to Use Just-In-Time Production

Just-in time (JIT), is a process that reduces costs and increases efficiency in business operations. It's the process of obtaining the right amount and timing of resources when you need them. This means that you only pay for what you actually use. Frederick Taylor, a 1900s foreman, first coined the term. After observing how workers were paid overtime for late work, he realized that overtime was a common practice. He then concluded that if he could ensure that workers had enough time to do their job before starting to work, this would improve productivity.

JIT is a way to plan ahead and make sure you don't waste any money. Also, you should look at the whole project from start-to-finish and make sure you have the resources necessary to address any issues. If you expect problems to arise, you will be able to provide the necessary equipment and personnel to address them. This way, you won't end up paying extra money for things that weren't really necessary.

There are many types of JIT methods.

-

Demand-driven: This JIT is where you place regular orders for the parts/materials that are needed for your project. This will allow for you to track the material that you have left after using it. You'll also be able to estimate how long it will take to produce more.

-

Inventory-based: This allows you to store the materials necessary for your projects in advance. This allows one to predict how much they will sell.

-

Project-driven: This is an approach where you set aside enough funds to cover the cost of your project. Knowing how much money you have available will help you purchase the correct amount of materials.

-

Resource-based JIT: This is the most popular form of JIT. This is where you assign resources based upon demand. You will, for example, assign more staff to deal with large orders. If you don't have many orders, you'll assign fewer people to handle the workload.

-

Cost-based: This is a similar approach to resource-based but you are not only concerned with how many people you have, but also how much each one costs.

-

Price-based: This is very similar to cost-based, except that instead of looking at how much each individual worker costs, you look at the overall price of the company.

-

Material-based: This is very similar to cost-based but instead of looking at total costs of the company you are concerned with how many raw materials you use on an average.

-

Time-based: Another variation of resource-based JIT. Instead of focusing solely on the amount each employee costs, focus on how long it takes for the project to be completed.

-

Quality-based: This is yet another variation of resource-based JIT. Instead of focusing on the cost of each worker or how long it takes, think about how high quality your product is.

-

Value-based JIT: One of the most recent forms of JIT. In this scenario, you're not concerned about how products perform or whether customers expect them to meet their expectations. Instead, your goal is to add value to the market.

-

Stock-based: This stock-based method focuses on the actual quantity of products being made at any given time. This is used to increase production and minimize inventory.

-

Just-in-time planning (JIT): This is a combination JIT and supply-chain management. It is the process that schedules the delivery of components within a short time of their order. It's important as it reduces leadtimes and increases throughput.