Logistics coordinators ensure that goods arrive on time and in a cost-effective manner. You'll be responsible for ensuring that goods get delivered to the customer in a timely fashion. Our article provides more information on logistics. We will also discuss the roles of customer service specialists, inventory analysts, and supply chain managers. The following are some of top jobs in logistics.

Logistics coordinator

Monster offers thousands of opportunities to find logistics coordinator jobs. This job requires extensive hands-on training. Candidates with minimal experience can usually take up training through an internship or apprenticeship, although they may also need to have some industry experience. You may be interested in a job as logistics coordinator if you have previous experience.

Customer service specialist

Customer service specialists are responsible for managing and delivering customer service. They are responsible for communicating with customers every day, coordinating inland transport, and resolving customer issues and complaints. They also manage customer relationships and coordinate appointments. You will coordinate and document all documents necessary to ensure delivery on time and within budget as a customer service specialist.

Inventory analyst

An Inventory Analyst is responsible for overall inventory productivity and service level maintenance. Their primary duties include managing inventory replenishment and order fulfillment for TSC Feed Programs. They support assortment and merchandise plans by managing inventory levels in their assigned product categories. They collect data and analyze trends to plan article-site replenishment at stores. They may also assist with marketing and promotional activities. They are responsible for analyzing sales data, and developing new strategies to increase business efficiency.

Supply chain manager

The supply chain manager manages the flow of goods and materials from suppliers to customers and manufacturers. A bachelor's degree is usually required for this role. Employers also prefer applicants with a master's degree in business administration. There are many options to get a job as a supply chain manager. Learn more about this career. Consider getting an associate's in business administration if you are interested in a career in supply chain management.

Freight agent

While you're creating your job description, make sure to include a section on your cargo and freight agent responsibilities. So that potential candidates can see what they have to do every day, the job description should include a list of key responsibilities. To attract qualified applicants, use strong action verbs. The job description should also include a detailed list of qualifications you need to fill this position.

FAQ

What is meant by manufacturing industries?

Manufacturing Industries are businesses that produce products for sale. Consumers are those who purchase these products. To accomplish this goal, these companies employ a range of processes including distribution, sales, management, and production. They manufacture goods from raw materials using machines and other equipment. This includes all types if manufactured goods.

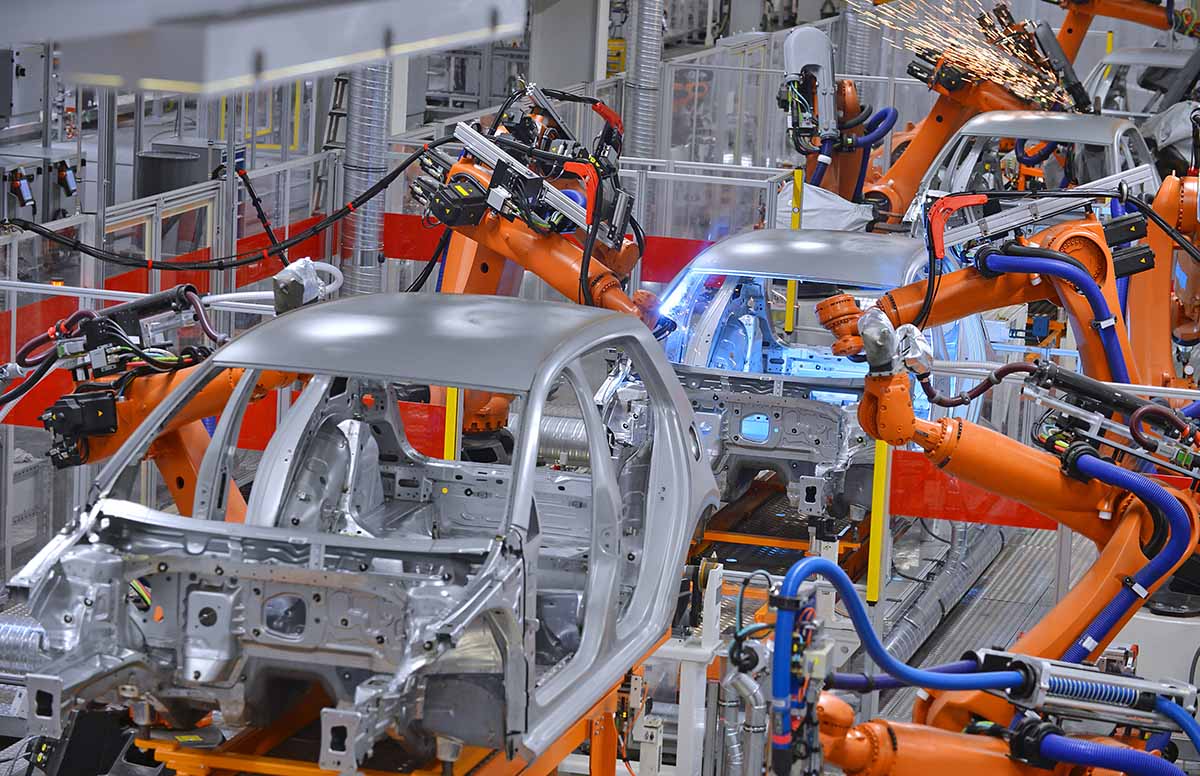

Can we automate some parts of manufacturing?

Yes! Yes. Automation has been around since ancient time. The Egyptians invented the wheel thousands of years ago. Nowadays, we use robots for assembly lines.

In fact, there are several applications of robotics in manufacturing today. These include:

-

Line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots that produce products

Manufacturing can also be automated in many other ways. 3D printing is a way to make custom products quickly and without waiting weeks or months for them to be manufactured.

What are the responsibilities of a logistic manager?

Logistics managers are responsible for ensuring that all goods arrive in perfect condition and on time. This is achieved by using their knowledge and experience with the products of the company. He/she must also ensure sufficient stock to meet the demand.

What does it mean to warehouse?

A warehouse is a place where goods are stored until they are sold. It can be an indoor space or an outdoor area. In some cases it could be both indoors and outdoors.

How important is automation in manufacturing?

Not only are service providers and manufacturers important, but so is automation. It enables them to provide services faster and more efficiently. They can also reduce their costs by reducing human error and improving productivity.

Statistics

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

External Links

How To

How to Use 5S to Increase Productivity in Manufacturing

5S stands to stand for "Sort", “Set In Order", “Standardize", and "Store". Toyota Motor Corporation created the 5S methodology in 1954. This methodology helps companies improve their work environment to increase efficiency.

The idea behind standardizing production processes is to make them repeatable and measurable. This means that tasks such as cleaning, sorting, storing, packing, and labeling are performed daily. This knowledge allows workers to be more efficient in their work because they are aware of what to expect.

There are five steps to implementing 5S, including Sort, Set In Order, Standardize, Separate and Store. Each step requires a different action, which increases efficiency. Sorting things makes it easier to find them later. Once you have placed items in an ordered fashion, you will put them together. Next, organize your inventory into categories and store them in containers that are easily accessible. Make sure everything is correctly labeled when you label your containers.

This requires employees to critically evaluate how they work. Employees should understand why they do the tasks they do, and then decide if there are better ways to accomplish them. To be successful in the 5S system, employees will need to acquire new skills and techniques.

The 5S method increases efficiency and morale among employees. They will feel motivated to strive for higher levels of efficiency once they start to see results.