Introducing kaizen into manufacturing processes may not be as easy as some may imagine. It is slow and takes time to get inventory and make sure everyone is on the same page. It depends on the problem area, level of participation and the size of the firm that is involved in this process. To ensure that your manufacturing process improvement initiative will be successful, follow the proper implementation methodologies and get the necessary resources. For this strategy to be successful, it is important to establish a strong company culture encouraging continuous improvement.

A company culture that focuses on improvement

Gallup polls show that only 32% percent of American employees are actively engaged in their jobs. Of those, 17.2% were actively disengaged. Kaizen culture is a way to increase employee engagement. This will result in improved processes, reduced turnover, and increased innovation. Engaged employees will be more open to new ideas and innovative thinking, which leads to increased productivity and customer satisfaction. Kaizen culture offers more benefits than reducing waste, increasing productivity, and increasing customer satisfaction.

Kaizen is a philosophy that encourages continuous improvement in every area of a business. Kaizen, which is an incremental improvement method, is better than making major, drastic changes that provide little to no benefit. Kaizen can help reduce costs, increase productivity, improve quality, and improve customer satisfaction when implemented properly. The philosophy also helps to improve employee morale.

There are many obstacles to implementing Kaizen in manufacturing

Even though there are many benefits to kaizen, they have their drawbacks. First, implementing kaizen requires significant changes in a business's management system. Once the changes are in place, it may be difficult to reverse the changes. Second, many businesses find it difficult or impossible to modify their existing work practices. This could hinder the implementation of kaizen.

Another issue is that many manufacturers are operating on a "feast/famine" cycle. If there is not enough demand for their products, a machine shop can run into problems. In such a case, the machine shop may have to close their doors and lay off employees. These machine shops can avoid the "feast-or-famine" cycle by implementing continuous improvement or kaizen. Kaizen can increase shop efficiency and allow shops to produce more.

Kaizen implementation in manufacturing is a success rate

The success rate of Kaizen implementations in the manufacturing sector is low, according to statistics. Only 10% percent of manufacturing companies have reported positive Kaizen outcomes. However, this doesn't mean that implementation is futile. Implementing Kaizen is an integral part of lean manufacturing. These are some ways to improve your manufacturing company's success rate.

Understanding the state of the world is essential to kaizen. Data is collected and analyzed in order to identify top priorities. Then, improvements are tested and verified by doing a before-and-after comparison. An analysis of the benefit-to-cost ratio can be used to analyze the overall impact of an improvement or the entire Kaizen process. It is essential to track the results of kaizen cycles for 60-90 days to gauge the effectiveness of the program.

FAQ

How can manufacturing avoid production bottlenecks

Avoiding production bottlenecks is as simple as keeping all processes running smoothly, from the time an order is received until the product ships.

This includes planning to meet capacity requirements and quality control.

This can be done by using continuous improvement techniques, such as Six Sigma.

Six Sigma is a management system used to improve quality and reduce waste in every aspect of your organization.

It focuses on eliminating variation and creating consistency in your work.

What skills are required to be a production manager?

To become a successful production planner, you need to be organized, flexible, and able to multitask. You must also be able to communicate effectively with clients and colleagues.

Why is logistics important for manufacturing?

Logistics are an essential component of any business. They enable you to achieve outstanding results by helping manage product flow from raw materials through to finished goods.

Logistics also play a major role in reducing costs and increasing efficiency.

How can manufacturing excess production be decreased?

In order to reduce excess production, you need to develop better inventory management methods. This would reduce the amount of time spent on unnecessary activities such as purchasing, storing, and maintaining excess stock. This could help us free up our time for other productive tasks.

This can be done by using a Kanban system. A Kanbanboard is a visual tool that allows you to keep track of the work being done. Work items are moved through various states to reach their destination in a Kanban system. Each state represents a different priority level.

For instance, when work moves from one stage to another, the current task is complete enough to be moved to the next stage. If a task is still in its beginning stages, it will continue to be so until it reaches the end.

This keeps work moving and ensures no work is lost. Managers can see how much work has been done and the status of each task at any time with a Kanban Board. This data allows them adjust their workflow based upon real-time data.

Lean manufacturing is another option to control inventory levels. Lean manufacturing is about eliminating waste from all stages of the production process. Anything that doesn't add value to the product is considered waste. Some common types of waste include:

-

Overproduction

-

Inventory

-

Packaging that is not necessary

-

Materials in excess

By implementing these ideas, manufacturers can improve efficiency and cut costs.

Statistics

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

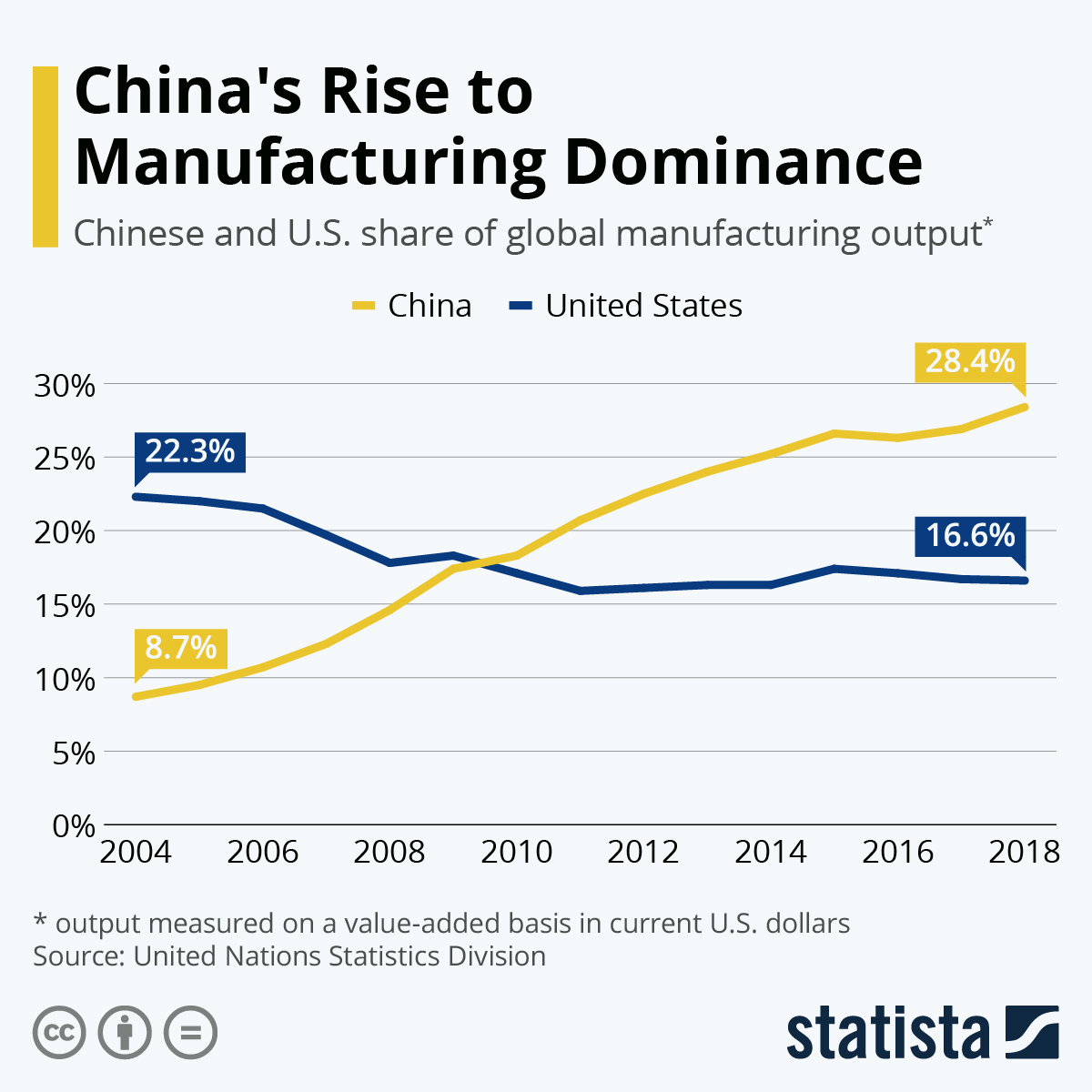

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

External Links

How To

How to Use Just-In-Time Production

Just-intime (JIT), a method used to lower costs and improve efficiency in business processes, is called just-in-time. This is where you have the right resources at the right time. This means you only pay what you use. Frederick Taylor first coined this term while working in the early 1900s as a foreman. After observing how workers were paid overtime for late work, he realized that overtime was a common practice. He concluded that if workers were given enough time before they start work, productivity would increase.

JIT is about planning ahead. You should have all the necessary resources ready to go so that you don’t waste money. It is important to look at your entire project from beginning to end and ensure that you have enough resources to handle any issues that may arise. You can anticipate problems and have enough equipment and people available to fix them. This will prevent you from spending extra money on unnecessary things.

There are many JIT methods.

-

Demand-driven: This type of JIT allows you to order the parts/materials required for your project on a regular basis. This will enable you to keep track of how much material is left after you use it. You'll also be able to estimate how long it will take to produce more.

-

Inventory-based: This is a type where you stock the materials required for your projects in advance. This allows you to forecast how much you will sell.

-

Project-driven: This means that you have enough money to pay for your project. You will be able to purchase the right amount of materials if you know what you need.

-

Resource-based JIT is the most widespread form. Here you can allocate certain resources based purely on demand. You will, for example, assign more staff to deal with large orders. If you don't have many orders, you'll assign fewer people to handle the workload.

-

Cost-based: This is a similar approach to resource-based but you are not only concerned with how many people you have, but also how much each one costs.

-

Price-based: This approach is very similar to the cost-based method except that you don't look at individual workers costs but the total cost of the company.

-

Material-based: This is quite similar to cost-based, but instead of looking at the total cost of the company, you're concerned with how much raw materials you spend on average.

-

Time-based: Another variation of resource-based JIT. Instead of focusing solely on the amount each employee costs, focus on how long it takes for the project to be completed.

-

Quality-based: This is yet another variation of resource-based JIT. Instead of thinking about how much each employee costs or how long it takes to manufacture something, you think about how good the quality of your product is.

-

Value-based: This is one of the newest forms of JIT. In this scenario, you're not concerned about how products perform or whether customers expect them to meet their expectations. Instead, you are focused on adding value to the marketplace.

-

Stock-based: This is an inventory-based method that focuses on the actual number of items being produced at any given time. It's useful when you want maximum production and minimal inventory.

-

Just-in-time (JIT) planning: This is a combination of JIT and supply chain management. It is the process that schedules the delivery of components within a short time of their order. It's important as it reduces leadtimes and increases throughput.