The duties and responsibilities of a mechanical engineering technician depend on their employer. They may test equipment, review blueprints, write purchase requests, and conduct research to help improve mechanical processes. They might also be exposed potentially hazardous materials. These risks are negligible if the procedures are followed.

While a mechanical engineer may supervise a technician who is a mechanical engineer, the technician's duties are typically performed independently. They are responsible to maintain and repair machinery and equipment. They are responsible for ensuring safety and compliance with company policies. Customers' requirements must also be met.

A skilled mechanical engineering technician can solve complex mechanical problems and provide accurate calculations. They will work closely with engineers to improve production. They may help to design new equipment and test materials.

A mechanical engineering technician should have a good understanding of principles and practices in mechanical engineering to be able to do the best job. They must also be skilled in the use of CAD software to design, analyze and optimize mechanical systems. They should also have the ability to keep mechanical service records. They must also have excellent time management skills.

The most common duties of a mechanical engineering technician are testing equipment and making estimates. They may also do research to improve manufacturing processes. These results are often recorded and evaluated, which makes them an integral part of the job description for a mechanical engineer technician.

A mechanical engineer technician also has to write work orders, interpret instructions, estimate the cost of labor and prepare sketches for components. Mechanical engineers may also test electrical systems, equipment, and materials to see how they work. They may also design machinery for power generation plants and other related equipment. They may also perform statistical studies to analyze the costs of production.

You will need to have solid knowledge about mechanical engineering principles and critical thinking skills. A working knowledge of new technology may be required. It is possible to collaborate with engineers to create schematics and other graphical representations, as well test them under various operational conditions.

The quality control analysis is an important aspect of a mechanical engineering technician’s job. Engineers perform quality control analysis by comparing tool drawings to the original specifications. They make recommendations and note the results. They may submit the results to engineers.

While a mechanical engineering technician may have to spend a lot of time working alone, they will typically work regular hours. They may also be required to work overtime. They might work in a laboratory, research facility, or manufacturing factory. They may work multiple hours and could be exposed to potentially toxic materials.

Mechanical engineers may also have to work with hydraulics or other power systems. They will be required to use power tools and rigging equipment every day and meet the demands of their customers.

FAQ

What is the role of a logistics manager

A logistics manager ensures that all goods are delivered on time and without damage. This is accomplished by using the experience and knowledge gained from working with company products. He/she must also ensure sufficient stock to meet the demand.

What is meant by manufacturing industries?

Manufacturing Industries are businesses that produce products for sale. Consumers are those who purchase these products. This is accomplished by using a variety of processes, including production, distribution and retailing. These companies produce goods using raw materials and other equipment. This includes all types and varieties of manufactured goods, such as food items, clothings, building supplies, furnitures, toys, electronics tools, machinery vehicles, pharmaceuticals medical devices, chemicals, among others.

Why is logistics important in manufacturing?

Logistics are an essential part of any business. They can help you achieve great success by helping you manage product flow from raw material to finished goods.

Logistics plays a significant role in reducing cost and increasing efficiency.

What is the importance of automation in manufacturing?

Automating is not just important for manufacturers, but also for service providers. They can provide services more quickly and efficiently thanks to automation. They can also reduce their costs by reducing human error and improving productivity.

Statistics

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

External Links

How To

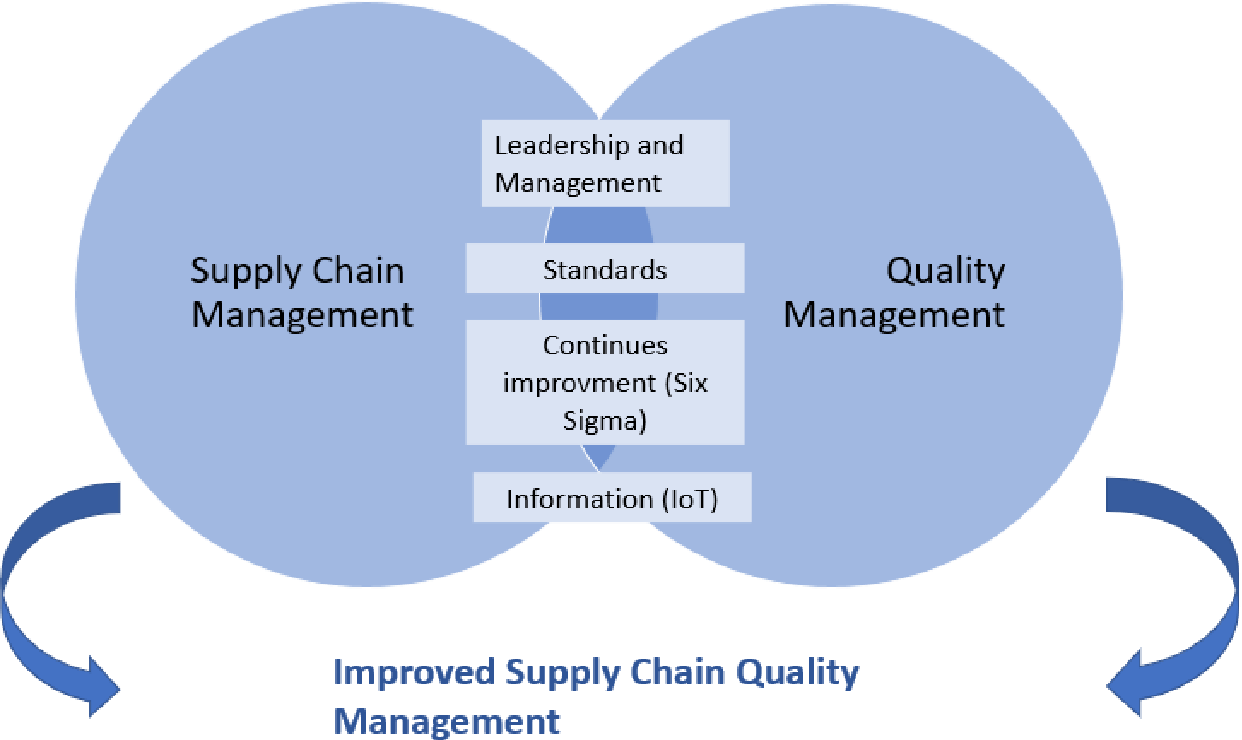

Six Sigma and Manufacturing

Six Sigma is "the application statistical process control (SPC), techniques for continuous improvement." Motorola's Quality Improvement Department developed it at their Tokyo plant in Japan in 1986. Six Sigma's basic concept is to improve quality and eliminate defects through standardization. In recent years, many companies have adopted this method because they believe there is no such thing as perfect products or services. Six Sigma aims to reduce variation in the production's mean value. If you take a sample and compare it with the average, you will be able to determine how much of the production process is different from the norm. If the deviation is excessive, it's likely that something needs to be fixed.

Understanding the nature of variability in your business is the first step to Six Sigma. Once you've understood that, you'll want to identify sources of variation. It is important to identify whether the variations are random or systemic. Random variations happen when people make errors; systematic variations are caused externally. These are, for instance, random variations that occur when widgets are made and some fall off the production line. But if you notice that every widget you make falls apart at the exact same place each time, this would indicate that there is a problem.

Once you identify the problem areas, it is time to create solutions. This could mean changing your approach or redesigning the entire process. Once you have implemented the changes, it is important to test them again to ensure they work. If they didn't work, then you'll need to go back to the drawing board and come up with another plan.